Tightening a tolerance from ±0.1 mm to ±0.05 mm increases your tooling costs and it provides zero functional benefit to your end-user. Many engineers assume high precision signals are high quality, but in injection molding, “perfect” is the enemy of “profitable.”

What Are Injection Molding Tolerances?

Injection molding tolerances define the allowable range of deviation for a finished part dimension. Because plastic is a dynamic material that expands with heat and shrinks as it cools, you can never achieve a 1:1 match with your CAD model. Experts express these deviations as a plus-or-minus value, such as 0.1mm.

It just means that if your design requirement is 50mm length, any part between 49.9mm and 50.1mm is a success. It is important to avoid chasing zero deviation because the last thing you want to do is pay for precision that the application does not require.

Types of Injection Molding Tolerances

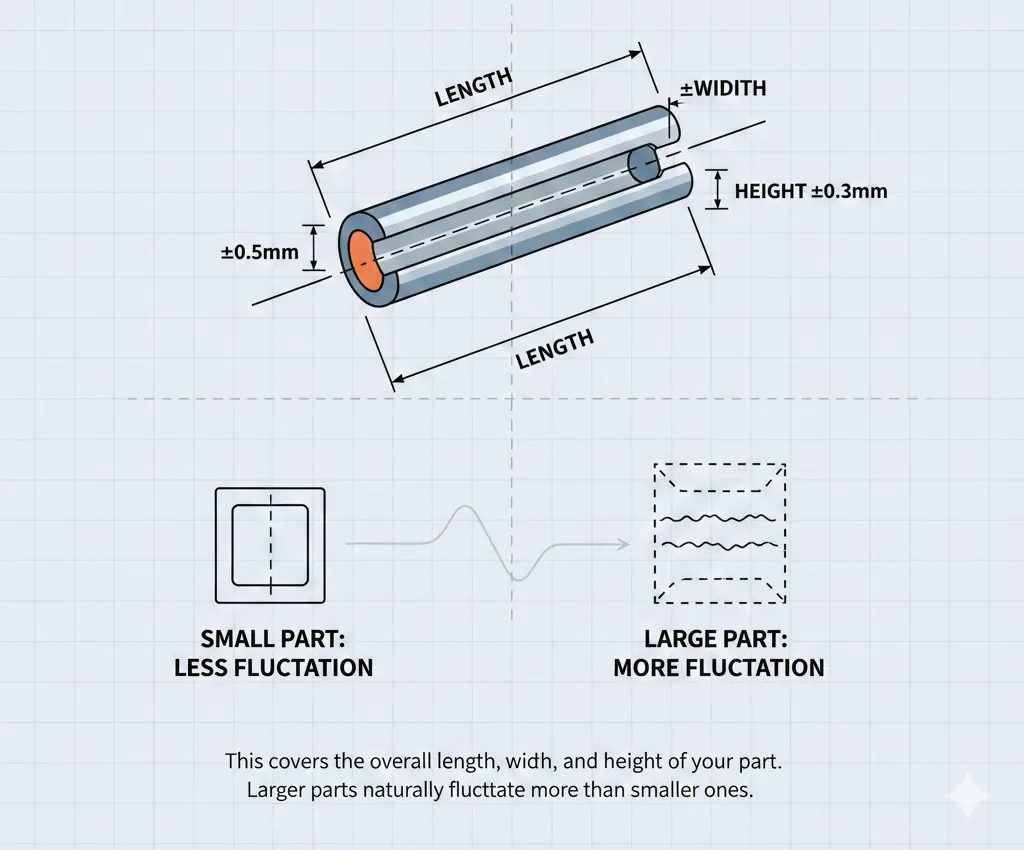

Dimensional Tolerances

This is the most common metric. It covers the overall length, width, and height of your part. You will need to account for the fact that larger parts naturally fluctuate more than smaller ones.

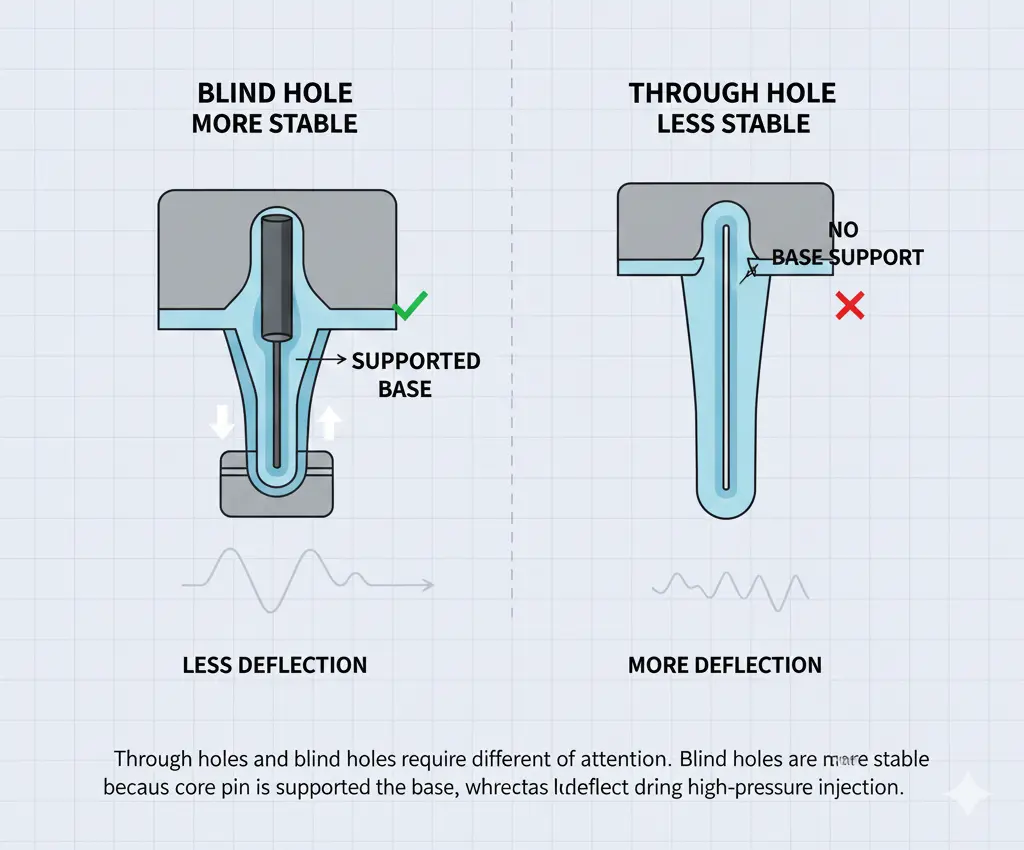

Hole Diameter Tolerances

Through holes and blind holes require different levels of attention. Blind holes are often more stable because the core pin is supported at the base, whereas long through-hole pins can deflect during high-pressure injection.

Straightness and Flatness

Large, flat surfaces are prone to bowing. This often just happens because the center of the part cools slower than the edges. There will be more variation on a flat tray than on a ribbed, structural component.

Wall Thickness Tolerances

Maintaining a uniform wall thickness is a helpful way to keep your dimensions stable. When walls vary in thickness, they shrink at different rates, pulling the part out of its intended shape.

Concentricity and Ovality

For circular features, the circles should stay round. In terms of assembly, if a cylinder becomes an oval, your bearings or mating parts will not seat correctly.

Tolerance Classes: Commercial vs. Fine

First, decide if your project falls into the Commercial or Fine category.

Commercial Tolerances: These are the industry standard, typically around $\pm 0.1mm$. They are cost-effective and suitable for most consumer goods.

Fine Tolerances: Fine tolerance reaches 0.025mm to 0.05mm. These are only for high-precision medical devices and complex mechanical assemblies.

It is better to have commercial tolerances. Select a part that is easier to manufacture than a “perfect” part that has a 40% scrap rate.

Standard Tolerance Values for Beginners

How often do you check the actual scale of your parts? Larger dimensions require wider “cushions.”

| Part Feature | Standard | Precision |

| Small Parts | ±0.10mm | ±0.05mm |

| Medium Parts | ±0.15mm | ±0.10mm |

| Large Parts | ±0.30mm | ±0.20mm |

Understanding Simplified Standards

The industry relies on ISO 20457 tolerance standard to categorize plastic moldings.

- Class A: High precision, often requiring expensive, hardened steel molds and climate-controlled production.

- Class B: Medium precision, which is the “sweet spot” for most technical parts.

- Class C: Low precision for non-critical items like toys or simple housings.

It is important to specify the ISO class on your 2D drawings so the molder knows exactly which quality gate to use.

Common Tolerance-Related Issues

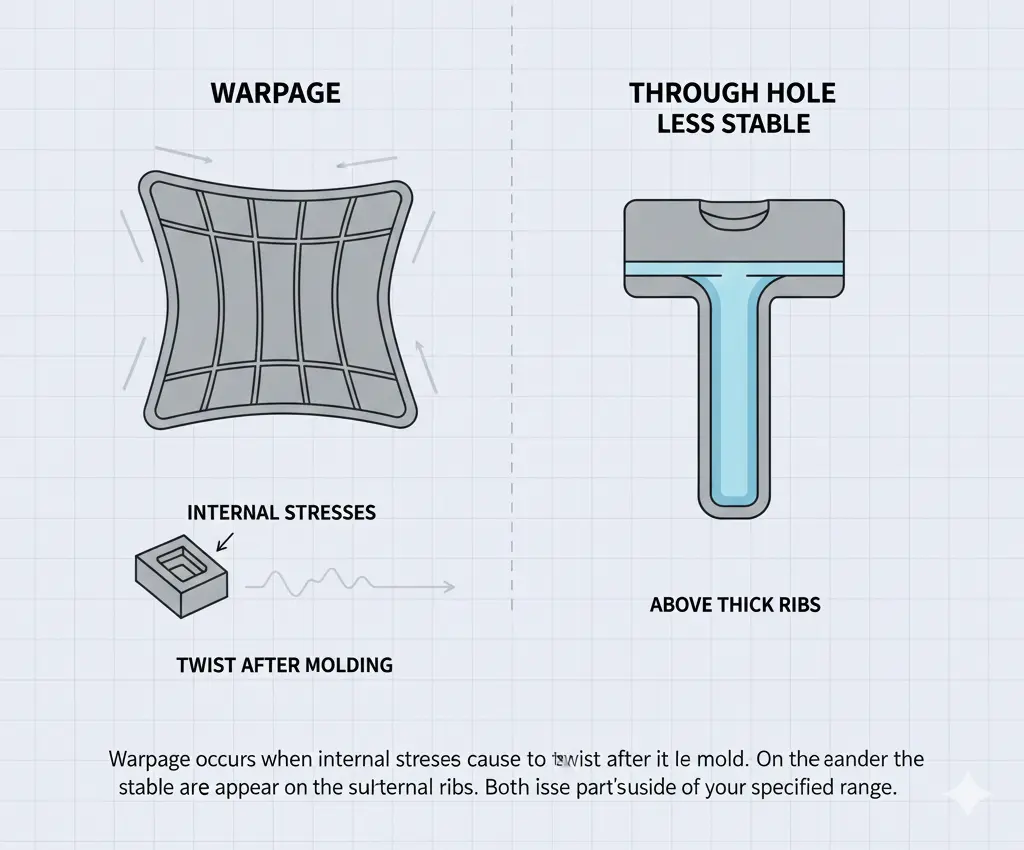

Warpage and Sink Marks

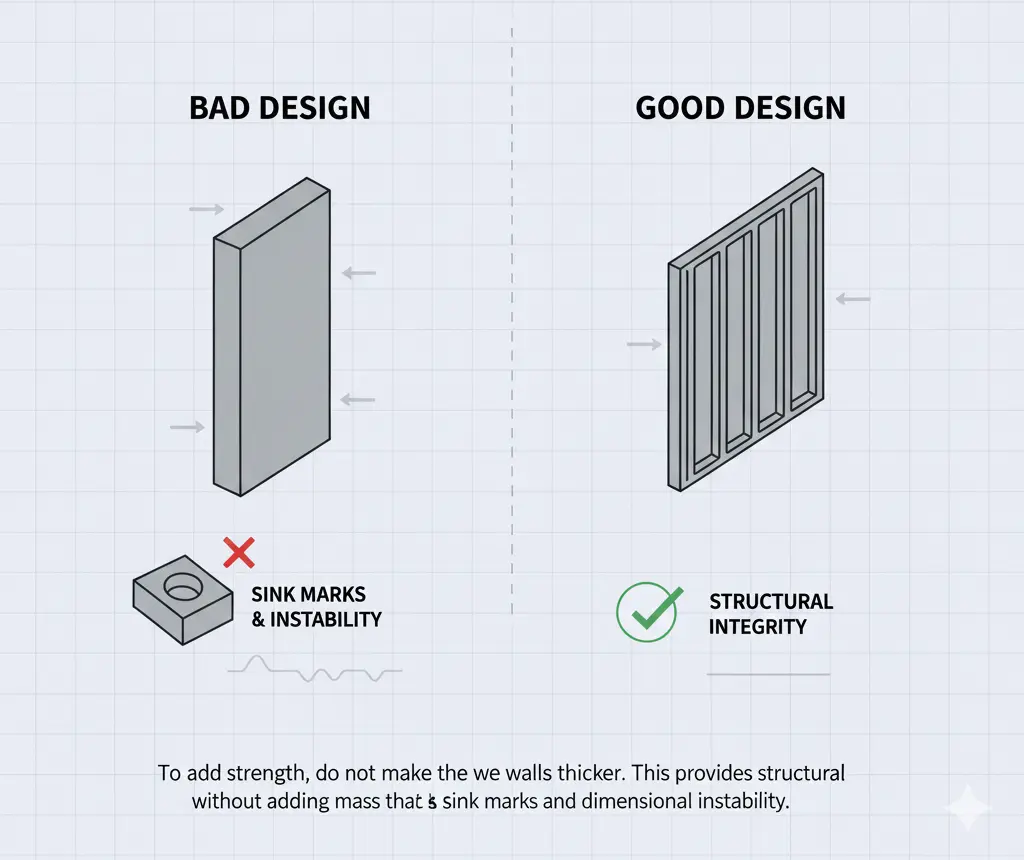

Warpage occurs when internal stresses cause the part to twist after it leaves the mold. On the other hand, sink marks are small craters that appear on the surface above thick internal ribs. Both issues can pull a part’s dimensions outside of your specified range.

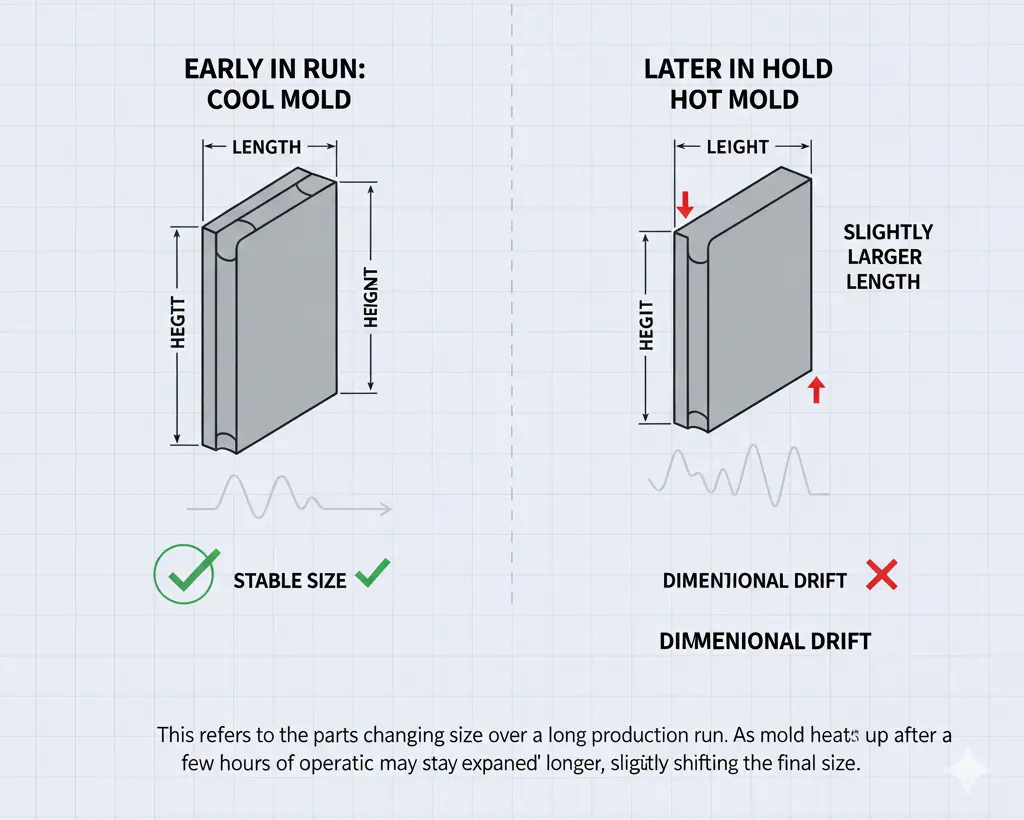

Dimensional Drift

This refers to the parts changing size over a long production run. As the mold heats up after a few hours of operation, the plastic may stay “expanded” longer, slightly shifting the final size.

Beginner’s Guide to Specifying Tolerances

Design Phase Best Practices

First, identify your Critical to Quality features. These are the 3 to 5 dimensions that actually matter for the product to function. You can then use general tolerances for everything else.

Communicating with Manufacturers

Sure, your CAD model is great, but it does not tell the whole story.Provide a 2D drawing that explicitly marks your CTQ dimensions. The best way to do this is to ask your molder: “What is the achievable tolerance for this specific material?”

Mistakes to Avoid

- Ignoring Shrinkage: Different plastics shrink differently. Nylon shrinks significantly more than ABS.

- Forgetting Draft: Without a 1.5 to 2-degree draft angle, the part will drag against the mold, ruining your tolerances and the surface finish.

Design Tips for Better Tolerance Control

Maintain Uniform Wall Thickness

Next, ensure your walls are consistent. If you must transition from thick to thin, use a gradual chamfer. This will happen to prevent “hot spots” that cause localized shrinkage.

Use Ribs Instead of Thick Walls

To add strength, do not make the walls thicker. Use ribs instead. This provides structural integrity without adding mass that leads to sink marks and dimensional instability.

Consider Gate Placement Early

The “gate” is where plastic enters the mold. Dimensions measured across the flow of plastic are usually more stable than those measured along the flow. Subsequently, discuss gate placement with your molder before they start cutting the tool.

Final Review

So, aside from the technical jargon, remember that injection molding is a game of heat management. You should be able to achieve great results by keeping your designs simple and your tolerances realistic.

FAQs

How would I find what kind of tolerances are achievable?

First, identify your resin’s shrink rate; for instance, ABS shrinks around 10.6%, while Polypropylene can jump to 21.5%. You can then use Moldflow Analysis software to simulate how that specific material behaves

How precise can injection molding be?

Industry-standard precision is ±0.005 for most commercial work. With tight process control, you can push to ±0.001.

What are the standard tolerances?

Commercial grade runs ±0.005 to ±0.010 depending on size. Fine tolerance is ±0.002 to ±0.005. Anything tighter than ±0.002 will cost more.

Is .005 a tight tolerance?

.005 is a standard commercial work. Tight starts around ±0.002″ where you need validated processes and consistent material lots. Anything under ±0.001″ is secondary operations.