Looking around, plastic products are everywhere—from everyday items like toothbrushes and water cups, to phone cases and the intricate keyboards and casings of laptops, all the way to the one-piece molded dashboards in cars. Have you ever wondered how these plastic parts, whether simple or complex, even those that fit together perfectly, are mass-produced identically? Behind this lies a mature industrial manufacturing technology: injection molding.

So, what exactly is injection molding? How does it replicate thousands of flawless products at astonishing speeds? This article will take you on a comprehensive journey into the secrets of the injection molding process.

I. What is Injection Molding?

Injection molding is a manufacturing techniques for plastic products: molten plastic is forcefully injected into the cavity of a metal mold. Once the plastic cools and hardens, the mold is opened to reveal a plastic part with a fixed shape.

The defining characteristic of injection molding is its ability to produce large quantities of complex plastic parts with exceptional repeatability at low cost and within extremely short cycles once the mold is fabricated. By adjusting process parameters and selecting different materials, properties such as heat resistance, impact resistance, transparency, or flexibility can be achieved. This fundamental capability is precisely why it has become the dominant technology in plastics processing.

II. Materials for Injection Molding

The strength of injection molding lies not only in its methodology but also in its broad compatibility with diverse material systems. Materials are the critical factor determining both the smooth execution of the process and the consistent quality of molded plastic parts. Different plastic materials not only dictate the product’s appearance, strength, and functionality but also influence the process parameters of the injection molding and the design of the mold. Therefore, understanding the types and characteristics of materials is an indispensable step in comprehensively mastering injection molding.

1. Thermoplastic Materials

Not all plastics are suitable for plastic injection molding. Thermoplastics, characterized by their ability to be repeatedly melted and reshaped, dominate the market, accounting for over 90% of all injection molding materials.

They are diverse and are typically categorized into two main groups based on their properties and applications: general-purpose plastics and engineering plastics. Their characteristics are summarized in the table below:

| Category | Material Name (Common Name) | Primary Characteristics |

| General-Purpose Plastics | ABS

(Acrylonitrile Butadiene Styrene) |

High strength, good toughness, easy surface coating, excellent overall performance |

| PP (Polypropylene) |

Lightweight, chemical resistance, fatigue resistance, non-toxic and odorless | |

| PE (Polyethylene) |

Good chemical stability, flexible, excellent insulation, easy to process | |

| PS (Polystyrene)) |

High rigidity, good transparency, low cost, but brittle texture | |

| Engineering Plastics | PA (Nylon) |

Excellent wear resistance, high strength, high toughness, self-lubricating |

| PC (Polycarbonate) |

Extremely high impact strength, high transparency, good heat resistance | |

| POM (Polyoxymethylene) |

High rigidity, low friction coefficient, excellent dimensional stability |

2. Thermosetting Materials

Unlike thermoplastics, thermosetting plastics soften initially when heated but undergo irreversible chemical reactions upon continued heating or catalyst addition, permanently curing into a solid form. Reheating does not melt them but causes carbonization. They typically exhibit outstanding heat resistance and dimensional stability.

Common Types: PR (Phenolic Resin), EP(Epoxy Resin), UP(Unsaturated Polyester), etc.

Typical Applications: High-temperature-resistant components like electrical switches, cookware handles, and automotive engine hoods.

3. Elastomers

Elastomers are essentially highly elastic thermoplastic or thermosetting materials, commonly used to manufacture soft, resilient products.

Common Types: Thermoplastic polyurethane, thermoplastic elastomers.

Typical Applications: Phone cases, sealing rings, shoe soles, soft grips, etc.

III. Injection Molding Process

The entire injection molding process comprises two major stages: mold making followed by mass production. First, based on the product’s 3 D design drawings, a steel mold with cavities matching the product’s shape is manufactured using precision techniques such as CNC machining and EDM (electrical discharge machining). This mold is then installed on an injection molding machine to enter the cyclic production phase: feeding, melting, injection, cooling and holding pressure, and demolding.

Every step of this precise cycle must be meticulously controlled, as even the slightest fluctuation in parameters—such as excessive temperature, insufficient holding pressure, or uneven cooling—can lead to defects of molded parts like shrinkage, flash, or short shots. Therefore, in bulk production, rigorous process monitoring and product inspection are essential to ensure consistent high quality across thousands of products.

IV. Injection Molding Machines and Molds

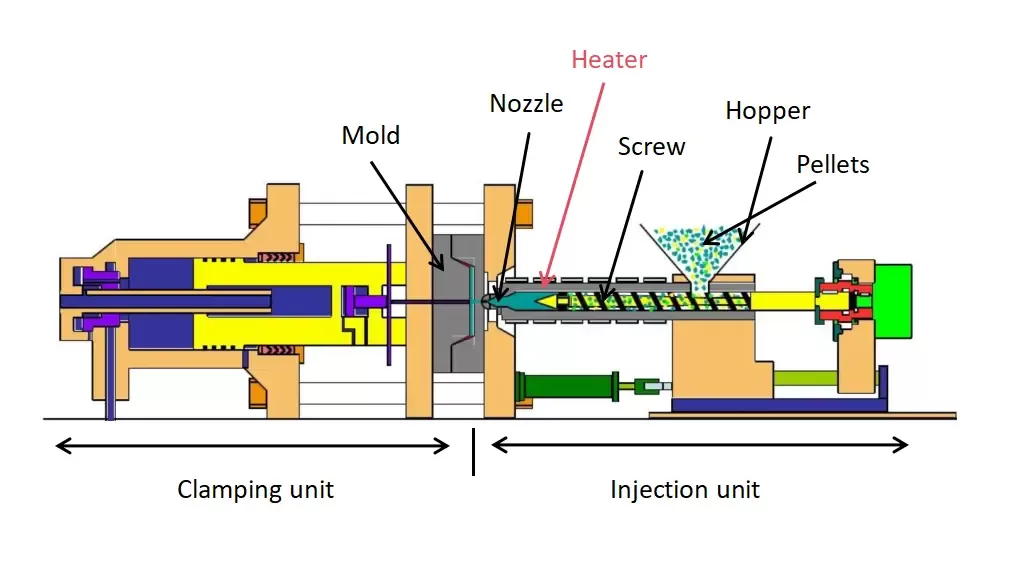

1. Injection Molding Machine

The injection molding machine is the core equipment in the molding process, consisting of the clamping unit, injection unit, and control system. The clamping unit opens and closes the mold and holds it firmly during molding. The injection unit feeds plastic through the hopper, melts it with the reciprocating screw, and injects it into the mold through the nozzle. The control system coordinates the whole process and regulates key parameters such as temperature, pressure, and speed. Together, these units enable raw plastic to be efficiently transformed into finished parts.

Injection Molding Machine

2. Classification of Machines (by Appearance)

Based on the spatial arrangement of the clamping unit and injection unit, the most common injection molding machines on the market are primarily categorized into the following two types:

| Category | Structural Layout | Appearance Characteristics | Key Advantages |

| Horizontal | Injection unit and clamping unit aligned parallel to the horizontal axis | Appears elongated, resting horizontally on the ground | 1. Suitable for automatic product ejection, facilitating full automation

2. Low profile facilitates operation and maintenance 3. Excellent stability for large-scale production |

| Vertical | Injection and clamping units aligned vertically | Tall and slender, standing upright on the floor | 1. Minimal floor space requirement

2. Simplifies insert installation (inserts can be placed smoothly) |

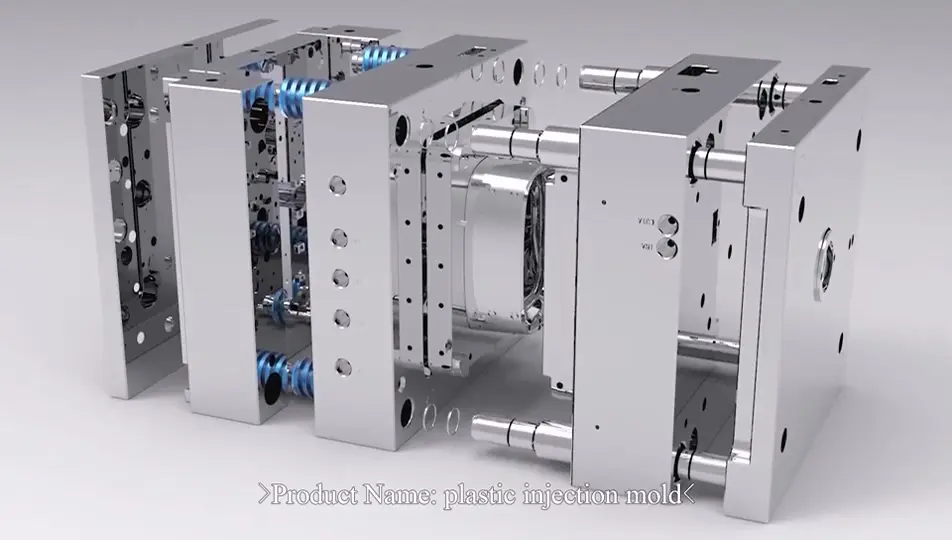

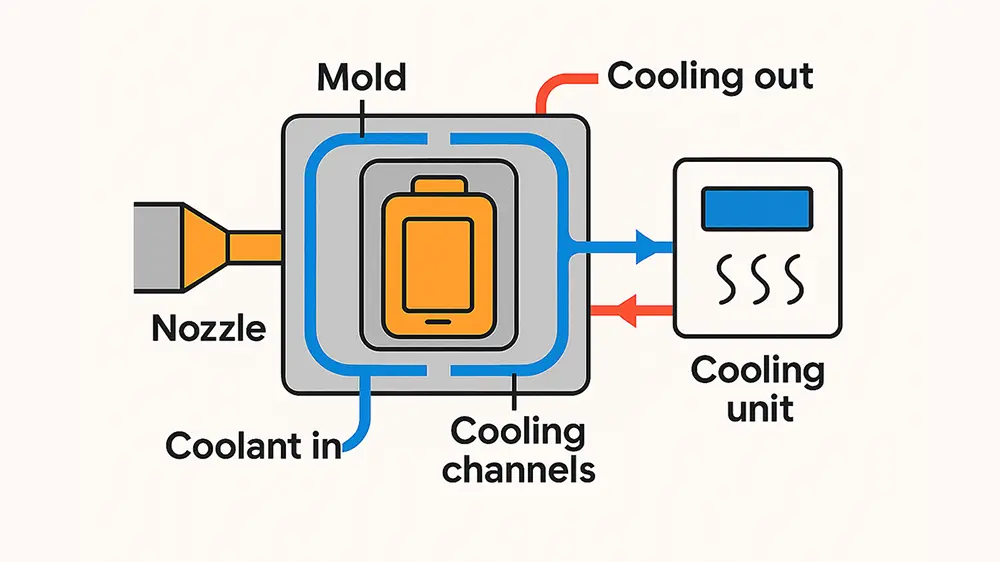

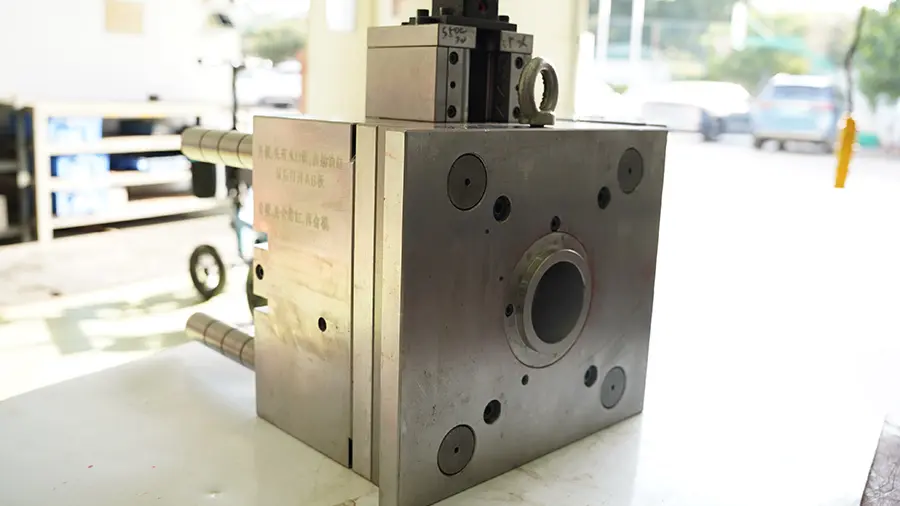

3. Injection Molds

Molds are metal cavities used to shape molten plastic, defining the form of all injection-molded products. They also determine geometric details, surface texture, precision, and consistency.

Basic Structure

Cavity: Composed of core and cavity, defining product shape, thickness, and details.

Runner System: Include sprue and gate entries into cavities, facilitating smooth flow of molten plastic from the injection machine into the mold.

Cooling and Ejection Mechanisms: Cooling channels are integrated to accelerate plastic solidification, while ejector pins facilitate smooth part removal after molding.

The parting line divides the mold into two halves: the moving mold and the fixed mold. The fixed mold is mounted on the injection machine’s fixed platen, typically housing the runner and gate. The moving mold is attached to the moving platen, responsible for the opening action and supporting the ejection system. Together, they form the complete cavity during mold closure.

Simple Classification

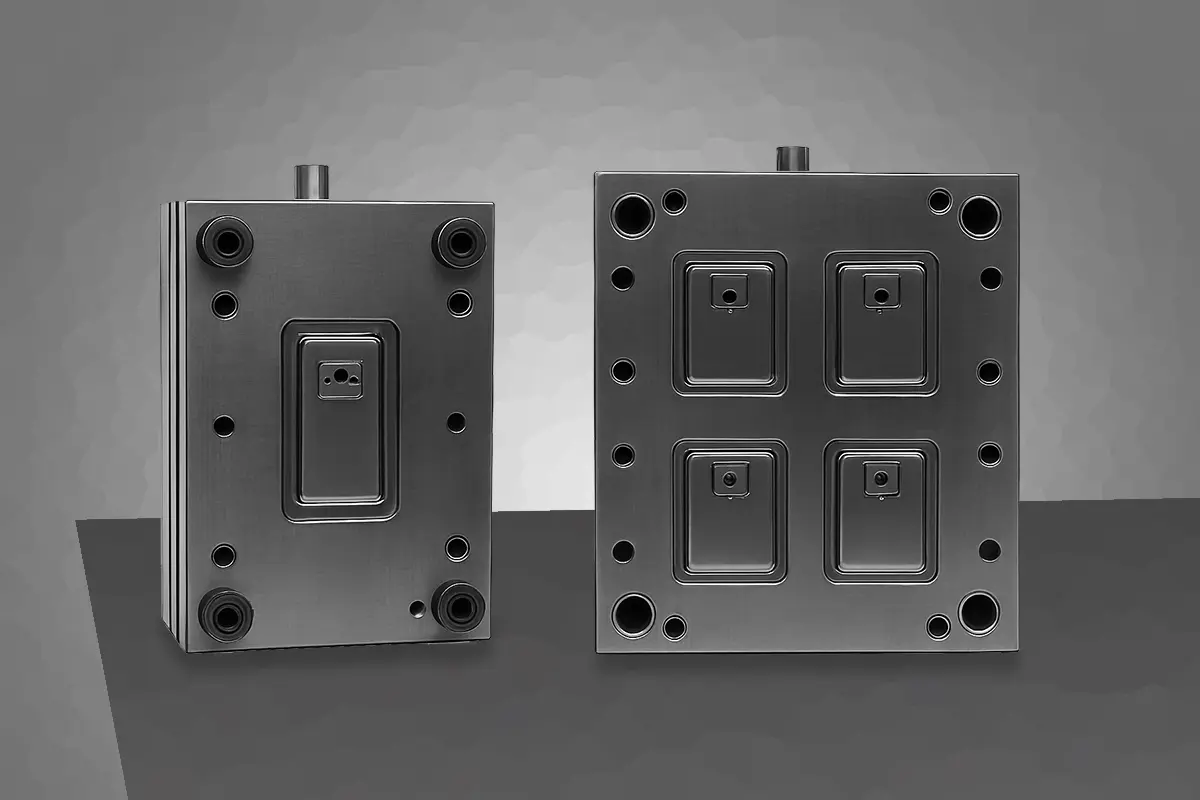

Single-cavity mold: A mold with only one cavity, producing one part per cycle. Suitable for large components or small-batch production.

Multi-cavity mold: A mold containing multiple cavities, enabling simultaneous production of several parts. Ideal for high-volume manufacturing of small items (e.g., bottle caps, LEGO bricks) with exceptional efficiency.

Single & Multi -cavity mold

V. Common Types of Injection Molding

To meet diverse product requirements, various different types of injection molding processes have emerged. These adaptations address changes in aesthetic demands, structural design, production efficiency, and functional performance. Below are the most prevalent injection molding methods in industrial production:

1. Traditional Injection Molding

This foundational and most widely applied process involves producing a single, complete part from a single material within one mold cycle. Most everyday plastic items, such as buckets, basins, and toys, originate from this method.

2. Two-shot Injection Molding

Two-shot injection molding uses two different colors or types of plastic to form a single-material, dual-color part within the same mold. Products feature a pleasant tactile feel, rich coloration, and eliminate the need for post-assembly.

3. Insert Molding

Insert molding involves placing metal components or other preforms into designated mold cavities before injection. Molten plastic is then injected, cooling to encapsulate and secure the insert, forming an integrated composite part.

4. Overmolding

Similar to insert molding, this process involves placing a molded plastic part into the mold cavity of an injection molding machine. After securing its position, a layer of soft plastic material is injected. This achieves a combination of hard and soft materials or enhances grip, slip resistance, and sealing properties. It also fulfills functions such as sealing, insulation, or improving aesthetics and tactile feel.

5. Thin-Wall Injection Molding

Specifically designed for producing parts with extremely low wall thickness (typically less than 1 millimeter). It imposes stringent demands on injection molding machines, molds, and materials, requiring extremely high injection speeds and pressures to ensure rapid and complete filling of thin-wall areas.If you are interested, please see the following article: Why Is Thin-Wall Injection Molding So Challenging?

6. Gas-Assisted Injection Molding

After injecting a portion of the molten plastic, high-pressure gas is introduced into the mold cavity. The gas propels the melt to fill the cavity, creating hollow gas channels within the product. This method reduces material consumption, prevents sink marks, and improves the surface quality of thick-walled parts.

VI. Advantages and Limitations of Injection Molding

In practical applications, injection molding performance varies depending on the product and process conditions. Understanding its strengths and limitations aids in making more informed decisions during production and equipment selection.

1. Advantages of Injection Molding

High Efficiency: Suitable for high-volume production with short cycle times.

High Precision: Molds control dimensions and details, ensuring stable finished product sizes.

Versatility: Supports diverse materials, colors, and functional combinations.

Automation: Synergy between injection molding machines and molds enables continuous production with minimal manual intervention.

Cost Advantage: Low unit cost and strong production controllability during large-scale manufacturing.

2. Limitations of Injection Molding

Common Defects: Injection-molded parts may exhibit various issues during forming, including warping, sink marks, bubbles or voids, short shots, scorching, flash, and weld lines. These defects are typically linked to mold design, material selection, injection machine parameters, and cooling control. Mitigation requires mold design optimization and process parameter management.

High Initial Investment: Tooling development cycles are lengthy, resulting in substantial upfront costs. However, costs per part decrease during production runs.

Complex/Ultra-Thin-Walled Parts: Demands high precision in injection processes, requiring more sophisticated equipment and control systems.

Limited Flexibility: Not suitable for small-batch production or scenarios with frequent design changes.

VII. Application Fields

Injection molding permeates nearly every aspect of modern life, from everyday household items to high-precision industrial components. Its efficiency and accuracy enable diverse products to meet varied demands for shape, function, and material. Below are key industries and scenarios showcasing typical applications:

Household Goods: Cups, bottles, tableware, home accessories, toys…

Consumer Electronics: Phone cases, laptop shells, headphone housings, remote control buttons, etc.

Automotive Components: Dashboards, bumpers, interior trim, air vents…

Medical Devices: Syringes, surgical instrument housings, laboratory vessels, IV sets, disposable medical supplies like test kits

Industrial & Mechanical Parts: Gears, housings, mechanical assemblies, brackets, protective sleeves

Packaging Containers: Food packaging boxes, beverage bottle caps, pharmaceutical containers, and other packaging products

VIII. Future Development Trends

With continuous advancements in manufacturing technology and materials science, injection molding is constantly evolving. Future injection molding processes will not only meet mass production demands but also become smarter, more efficient, and more environmentally friendly. New technological developments are transforming production methods, enabling injection molding to handle more complex designs, diverse materials, and stricter quality requirements.

1. Automation and Intelligence

As manufacturing technology advances, injection molding machines are becoming increasingly automated. From automatic feeding and mold opening/closing to robotic part removal and stacking, many steps once reliant on manual labor are now automated. This not only reduces human error but also stabilizes and enhances production efficiency, maintaining consistent cycle times and quality during mass production.

The introduction of IoT technology has made production processes smarter and more traceable. Real-time data sharing and remote monitoring between devices not only optimize production efficiency but also enhance fault early warning capabilities and maintenance efficiency, making the entire production process more flexible and efficient.

2. New Materials and Processes

The development of high-performance engineering plastics has opened new horizons for injection molding. Specialized materials with properties like high-temperature resistance, corrosion resistance, and electrical/thermal conductivity are emerging to meet demands in high-end sectors such as aerospace and new energy vehicles. Concurrently, innovative processes like multi-material injection molding and 3D injection molding enable the fabrication of complex structural components in a single operation.

3. Micro-Injection Molding and High-Precision Forming

The trend toward miniaturization in medical devices and electronic components has created vast opportunities for micro-injection molding. This process produces parts weighing mere milligrams with micron-level precision, imposing new demands on mold machining, equipment control, and material handling. Advances in precision injection molding are continually pushing the boundaries of manufacturing.

4. Green Manufacturing and Sustainable Development

Sustainability principles are profoundly reshaping the injection molding industry. The application scope of recycled plastics, biodegradable plastics, and reclaimed materials continues to expand, while energy-efficient all-electric injection molding machines gradually replace traditional hydraulic equipment. Low-energy mold design and eco-friendly processes will become dominant trends, driving more environmentally conscious production and efficient resource utilization.

Conclusion

In summary, injection molding is a manufacturing process characterized by clear structure, mature workflows, and extensive applications. From material selection and process steps to the fundamental composition of equipment and molds, and encompassing various molding methods, its system is highly refined. By examining these key elements, readers can gain a comprehensive understanding of the fundamental principles and practical applications of injection molding. As technology and equipment continue to advance, this process will continually adapt to new materials, evolving product demands, and emerging production models, expanding its role across broader industries.