Welcome to the world of CNC machining, where precision meets technology to revolutionize modern manufacturing. CNC, short for Computer Numerical Control, is a process that utilizes computerized systems to control machine tools.

Like mills and lathes to create intricate parts with unmatched accuracy. The key components of CNC machining include the CNC machine and various types, such as milling machines and routers. And the essential aspect of CNC programming that dictates the movements and operations.

This blog post will delve deeper into CNC machining, exploring its significance in today’s manufacturing landscape and shedding light on its role in streamlining production processes. It will cover everything from understanding how numerical control machines operate to uncovering the diverse applications of CNC technology across industries.

We can also comprehensively understand CNC machining’s definition, process intricacies, and crucial components. Join us on this journey through the fascinating world of computer-controlled precision engineering. Discover the endless possibilities that unfold when you embrace the power of CNC technology.

What is CNC Machining?

CNC machining revolutionized the manufacturing process by automating precision tasks once done by hand. CNC stands for Computer Numerical Control, encompassing diverse machines like CNC mills, lathes, routers, and drillers.

These machines use coded instructions to sculpt raw materials into finished parts with unrivaled accuracy. From crafting intricate machine parts to creating prototypes swiftly. The versatility of CNC technology makes it indispensable in various industries.

The history of CNC machining traces back to numerical control systems developed in the mid-20th century. Over time, these systems evolved into sophisticated CNC machines that operate seamlessly through electrical discharge and milling techniques.

Today’s workshops rely on different CNC units tailored for specific tasks: a detailed CNC router for artistic designs or a robust CNC lathe for heavy-duty manufacturing processes. Effortlessly blending creativity and precision, CNC machinists continue to push boundaries in advanced manufacturing technologies.

How CNC Machining Works?

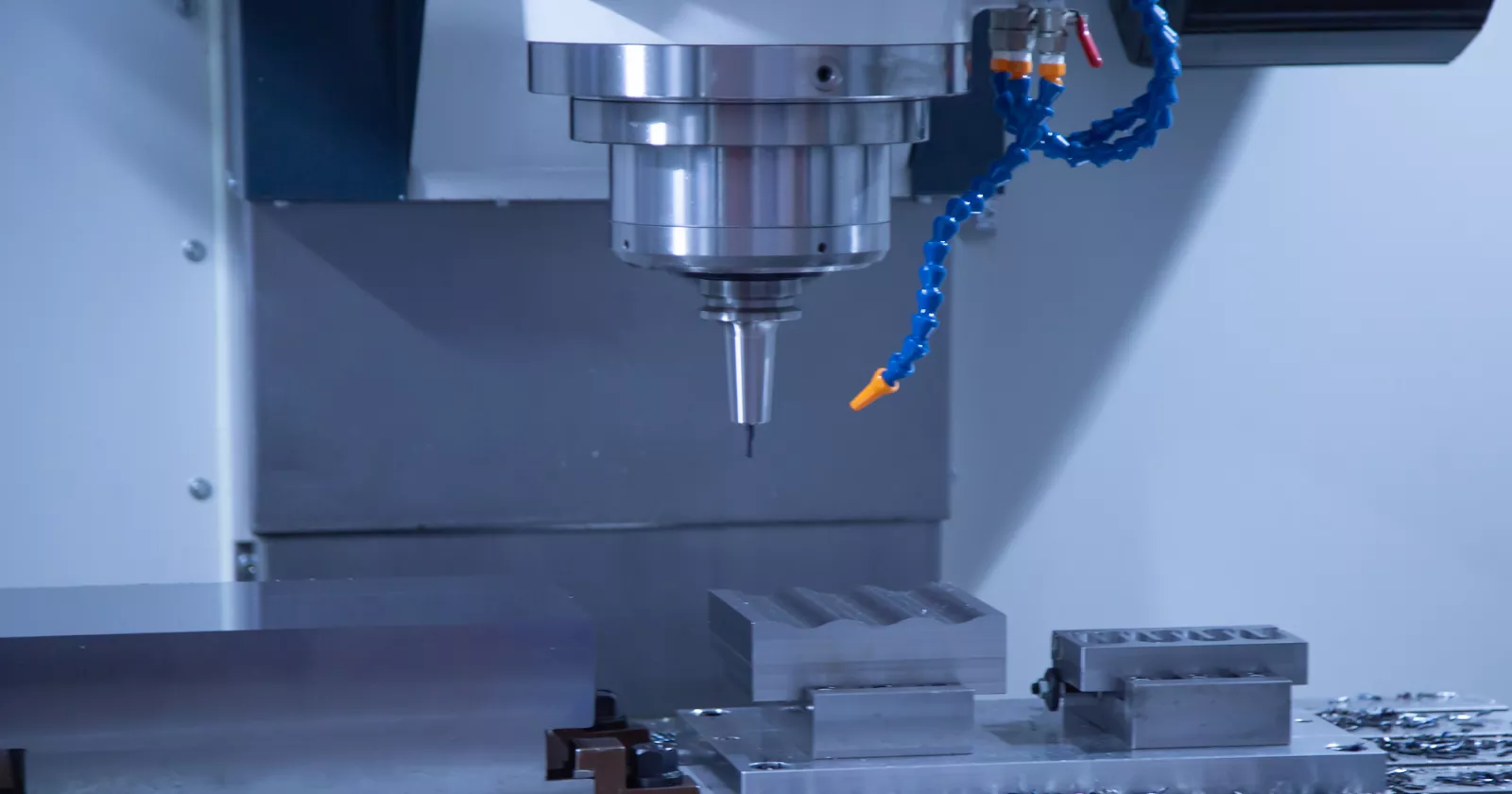

CNC machining involves an intricate manufacturing process where various CNC machines create precise machine parts. CNC mills, lathes, routers, and drilling machines are crucial in this advanced technology. CNC milling machines use computer programming to move the cutting tool in different directions to create the desired shape. On the other hand, CNC lathes rotate the material being worked on while a fixed cutting tool shapes it.

CNC machines’ versatility and accuracy make them indispensable in modern manufacturing processes. Whether CNC drilling or electrical discharge machining, these tools offer unparalleled precision and efficiency. Understanding the different types of CNC machines and their applications can open up a world of possibilities for skilled machinists in CNC manufacturing.

- Designing the CAD Model

When it comes to CNC machining, the design of the CAD model plays a crucial role in guiding the entire process. Computer-aided design allows precise specifications inputted into CNC machines, enabling them to create intricate parts with consistent accuracy.

Unlike manual machining, CNC turning and other capabilities allow operators to fabricate components with minimal human intervention. The evolution of CNC machine tools has revolutionized manufacturing by streamlining operations and increasing efficiency.

Learning about how CNC machining works unveils a world where complex designs are transformed into tangible products rapidly and accurately. This subtractive manufacturing process is possible through standard CNC machines that use computer programs to direct cutting tools on lathe machines. Understanding the intricacies of CNC machining opens doors to limitless possibilities in modern production processes.

- Converting CAD Files to CNC Programs

Converting CAD files to CNC programs is a critical step in the fascinating world of CNC machining. CAM software plays a vital role in this process, translating complex designs into instructions that CNC machines can understand. G-code and M-code basics are the language through which these instructions are communicated, dictating movement, speed, and various machine functions.

Understanding how CNC machining works unlocks a realm of possibilities. Imagine transforming raw materials precisely using CNC turning or other common CNC machines. Each step reveals the artistry behind manufacturing processes, from manual machining on a lathe machine to operating advanced CNC machine tools. Machining is a subtractive manufacturing method where the material is gradually removed to create intricate components – all made possible by the magic of CNC technology.

The evolution from traditional methods to embracing the use of CNC has revolutionized the industrial landscape, shaping how we perceive production efficiency and quality assurance in modern times.

- CNC Machine Setup

One of the most crucial aspects of CNC machining is the setup process, encompassing various intricate steps essential for seamless operation. From preparing the machine and material to meticulously selecting and installing tools, each stage plays a pivotal role in executing precise cuts efficiently. As CNC machines are used across diverse industries, understanding the intricacies of this technology is paramount for any CNC operator.

Mastering how CNC machining works involves delving into subtractive machining technology where modern CNC machines shine. These cutting-edge devices, employed to control and cut materials with unparalleled accuracy, offer a glimpse into the vast possibilities within manufacturing. These versatile machines can also be tailored to accommodate different operations based on specific project requirements, whether utilized in milling, turning, or drilling.

The allure of CNC machining lies in its technical prowess, adaptability, and precision, which revolutionize conventional machining processes. One can truly grasp the transformative power underlying every step of the CNC machining journey by exploring how these advanced machines are harnessed to transform raw materials into intricate components.

- Executing the Machining Operation

Imagine stepping into a world where precision meets innovation in CNC machining. As the CNC operator sets the program, a symphony of machines comes to life, ready to sculpt raw materials into intricate masterpieces. From milling to turning, each process unfolds with calculated perfection. Monitoring every detail, the operator ensures seamless execution from start to finish.

In modern CNC machining, technology reigns supreme. These machines are used for cutting, engraving, and shaping with unparalleled accuracy. The beauty lies in the result and the dance of control and precision throughout the operation.

It’s fascinating to witness how different types of CNC machining operations work harmoniously under one roof, showcasing efficiency at its finest. Let’s delve deeper into this subtractive machining technology and unravel its wonders together.

Key Components of CNC Systems

At the heart of modern manufacturing, CNC (Computer Numerical Control) systems are the cornerstone, revolutionizing how we create everything from simple parts to complex components. To fully appreciate and learn what CNC machining offers, it’s crucial to delve into its key components and how they synergize to deliver precision and efficiency.

CNC Machine Types:

- Mills:CNC machining workhorses are used to cut and shape metal and other highly precise materials.

- Lathes:Specialized for turning operations, they rotate the workpiece against the cutting tool, ideal for creating cylindrical parts.

- Plasma Cutters:Utilize a high-velocity jet of ionized gas to cut through metal by melting it away, perfect for complex metal shapes.

CNC machining is a subtractive manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. This technology can control a range of complex machinery, from grinders and lathes to mills and routers. With the advancement of CNC technology, 5-axis CNC systems have emerged, offering the advantages of CNC machining by allowing multiple axes of movement simultaneously, significantly enhancing precision, efficiency, and the ability to create complex geometries.

Types of Cutting Tools:

- End Mills:Used in milling applications like face milling and profile milling.

- Drill Bits:Designed to drill holes in the material.

- Turning Tools:These are employed in lathes to remove material from the workpiece, creating cylindrical parts.

Workholding devices are the unsung heroes of CNC machining, ensuring that materials stay in place during the machining process. These devices range from vises and clamps to custom jigs that hold workpieces in the optimal position for machining.

Choosing a work-holding device is critical, as it directly affects the finished product’s precision, efficiency, and quality. CNC machining and CNC systems benefit greatly from the innovation and reliability provided by modern workholding solutions, highlighting the intricate dance between machine, tool, and material in the manufacturing process.

CNC Machining Operations

CNC Machining Operations encompass many techniques used in the manufacturing sector to shape metal and other rigid materials, utilizing precise computer controls. This machining is a manufacturing process where pre-programmed software dictates the movement of factory tools and machinery. It’s fascinating how a single set of computer commands can transform a raw material into a final product with extreme precision.

- Drilling: A quintessential process used in CNC, drilling creates cylindrical holes in a workpiece. CNC machines can execute this operation with high accuracy by using a rotating drill bit, making it a staple in manufacturing. It’s fascinating how this technique can be adapted to various materials and depths, showcasing the versatility of CNC equipment.

- Milling: Milling is a popular CNC machining operation where a rotating cutting tool removes material from the workpiece. This process can create various shapes and features, including slots, holes, and complex surface contours. The ability to switch between different milling cutter types makes it incredibly adaptable for intricate designs and finishes.

- Turning: When using a CNC machine for turning, the workpiece rotates while a cutting tool moves in a linear path. This machining process of turning is instrumental in creating symmetrical objects such as cones, cylinders, and disks. Its precision and efficiency highlight the advanced capabilities of CNC machining equipment and machine training.

Advanced operations take CNC machining into the realm of near-miraculous manufacturing techniques, expanding its applications:

- Electrical Discharge Machining (EDM): This advanced process uses electrical sparks to mold a material into a specific shape. EDM showcases innovation in machining, which can cut intricate contours or cavities in pre-hardened steel without direct contact, thus minimizing mechanical stresses.

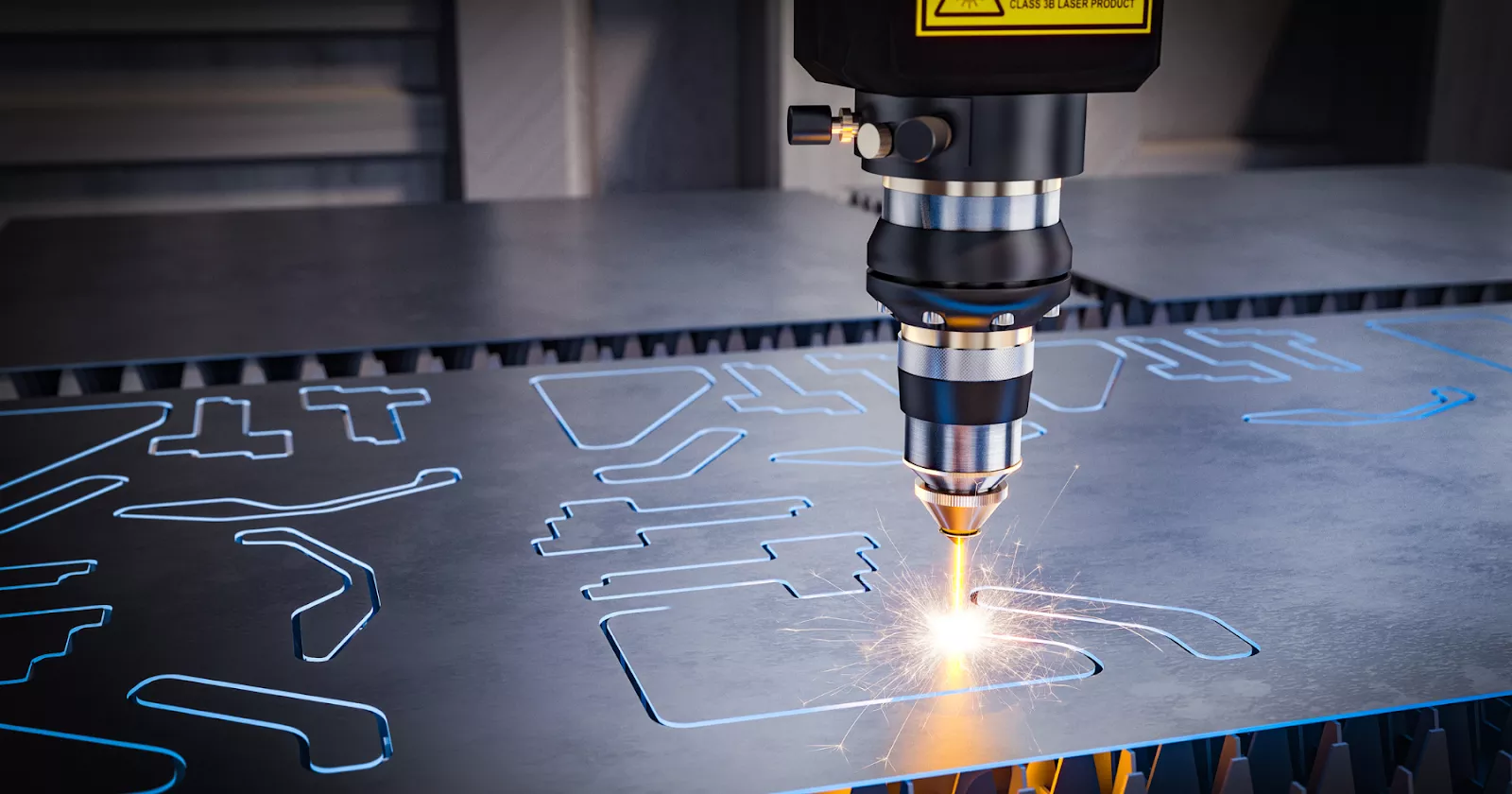

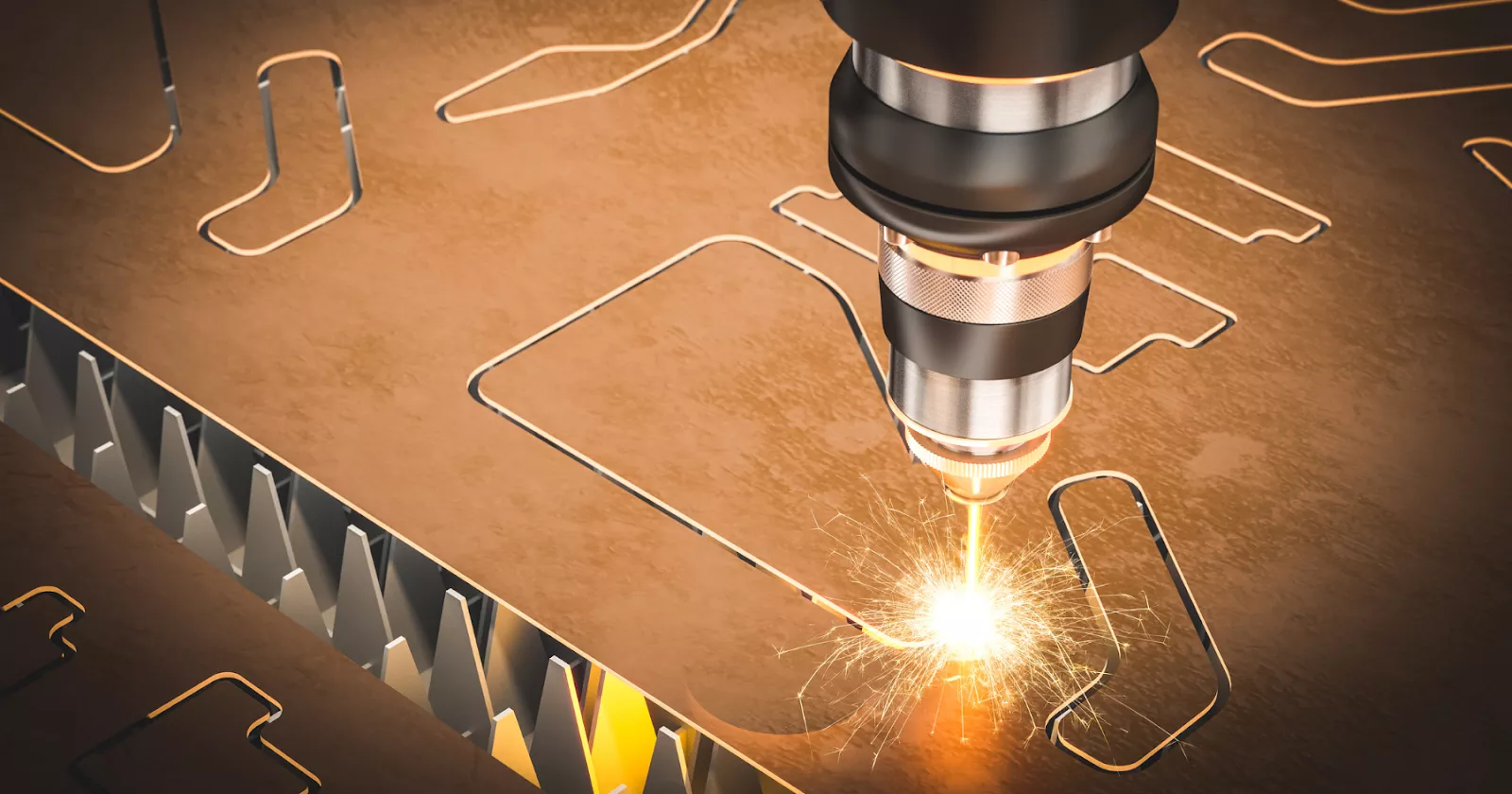

- Laser Cutting: Laser cutting stands out for its precision and versatility. It employs a high-powered laser to cut or engrave materials ranging from metals to plastics. The process is renowned for its accuracy, speed, and flexibility, making it suitable for various applications of CNC machining. Laser cutting exemplifies how advanced technology can control machining processes, offering an unmatched level of detail and finish.

Materials Compatible with CNC Machining

CNC machining stands out in manufacturing for its precision, efficiency, and versatility. The materials that can be skillfully shaped into desired forms are at the heart of this technique. Let’s dive into the types of materials suitable for CNC machining and the selection criteria to ensure optimal application.

Materials Compatible with CNC Machining

- Metals:

- Aluminum: Known for its lightweight and strength, aluminum is a favorite for aerospace and automotive parts.

- Steel: Offers robustness for industrial components. Stainless steel, in particular, is sought after for its corrosion resistance.

- Brass: Finds its niche in electrical components due to its excellent conductivity.

- Plastics:

- Acrylic: Ideal for transparent applications with its clarity and resistance to breakage.

- Nylon: Valued in automotive and mechanical parts for its durability and wear resistance.

- ABS: A common choice for prototypes due to its strength and ease of machining.

- Other Materials:

- Wood: CNC machining carves intricate designs in wood for decorative and functional items.

- Foam: Used for models and prototypes, foam is easily shaped by various CNC machines.

Selection Criteria Based on Application

- Strength and Durability:Essential for parts subjected to stress, like in automotive or aerospace industries.

- Corrosion Resistance:A must for components exposed to harsh environments, ensuring longevity.

- Electrical Conductivity:Crucial for electrical and electronic components, dictating the choice of metals like brass.

- Aesthetics and Finish:Consideration for consumer goods where the visual appeal is as important as functionality.

- Cost-Effectiveness:Balancing material properties with budget constraints to optimize manufacturing efficiency.

The Significance of CNC Machining in Various Industries

CNC machining, a cornerstone in modern manufacturing, is pivotal across numerous industries. Its significance is magnified by the advent of various types of CNC machines and the versatility of CNC machining processes. Here’s how it impacts different sectors:

- Aerospace:CNC machining services are crucial for producing high-precision components essential for flight and safety. The intricacy of aerospace parts, coupled with the demand for materials that can withstand extreme conditions, highlights the importance of CNC machining. Processes like CNC drilling ensure parts meet the aerospace industry’s strict tolerance and durability requirements.

- Automotive:In automotive manufacturing, CNC machining allows for the high precision and reliability vehicles require. From engine components to custom fittings, the CNC machining process offers unparalleled accuracy and speed, ensuring the performance and safety of automotive products.

- Medical Applications:The medical industry benefits from CNC machining by creating complex, bespoke medical devices and implants. The precision of CNC machining processes, especially when working with various CNC machining materials, is critical for producing items that comply with rigorous health standards.

- Custom Parts Production:The ability to produce custom parts swiftly and accurately is a hallmark of CNC machining. Whether it’s a unique component for a specific machine or a bespoke product, CNC machining services cater to diverse needs, making innovation and customization more accessible.

- Prototyping:CNC machining is instrumental in prototyping from the concept stage to the final product. The CNC machining process begins with a design, quickly bringing ideas to life with precision. This rapid prototyping capability enables industries to test and refine their products efficiently, significantly reducing the time to market.

CNC machining bridges the gap between imagination and reality. Whether through a CNC lathe machine or various CNC machining processes. The ability to turn a digital design into a tangible product with speed, accuracy, and efficiency underscores its importance across industries. Products produced by CNC not only meet the high standards required in sectors like aerospace and automotive. And medical but also push the boundaries of what’s possible in custom parts production and prototyping.

Future Trends in CNC Machining

Automation and AI are at the forefront, revolutionizing how CNC machines are used, enhancing efficiency, and expanding capabilities. CNC machining makes it possible for complex designs to come to life with unparalleled accuracy. As automation integrates into this sphere, the role of a CNC machinist evolves, demanding new skills to manage and optimize these intelligent systems. AI’s influence means CNC machine feeds, milling, and turning machines are not just operated but are collaborators in the manufacturing process, capable of self-optimization and learning.

Technological innovations equip CNC mills with advanced sensors and software, enabling predictive maintenance and quality control like never before. The industry heavily relies on CNC to produce with minimal error and maximal efficiency.

With AI, CNC machines can work autonomously, adjusting parameters in real-time for the CNC milling process and foreseeing potential issues before they arise. This shift towards more innovative machines includes the growing presence of milling and turning machines that self-adjust, ensuring optimal performance.

Common types of CNC machines, including routers, grinders, and lathes, now benefit from these technological leaps. CNC machining terminology is also expanding, reflecting the integration of new technologies that enhance the capabilities of these machines. As the industry moves forward, becoming a CNC machinist will increasingly mean interfacing with technology that automates, innovates, and elevates the precision and possibility of what CNC machining can achieve.

Conclusion

Understanding CNC machines unfolds the extensive possibilities and innovative landscape of modern manufacturing. Through the lens of CNC technology, we’ve explored how these machines eliminate manual labor’s margin for error, offering nothing short of revolutionary precision. CNC mills come in various forms, each designed to meet specific needs, highlighting the technology’s versatility. We’ve seen how this technology adapts to various industries, from the parts processed by CNC machines to the different types of machines available.

The machining process that uses computer numerical control is not just about what’s being created today but also paves the way for future innovations. The main types of CNC, including routers, mills, and lathes, continually expand the scope of CNC machined parts. Materials used in CNC machining, including drilling, milling, and turning, show the breadth of possibilities.

These machines provide solutions that can also control complex operations, ensuring that a CNC machine understands and executes designs with unprecedented accuracy. Looking ahead, the trajectory of CNC technology promises even more sophisticated applications, reinforcing its indispensable role in pushing the boundaries of what can be imagined and achieved. Through its adaptability and efficiency, CNC machining is a cornerstone of modern manufacturing and a beacon for future advancements.