Mold injection customization manufacturers are faced with a plethora of choices when it comes to what type of mold they want to use for their project.

While there are many factors to consider when making this decision, the final choice often depends on the specific needs of the customer and the project. In some cases, a more specialized mold is required to produce the desired results.

Here we will learn about MMIC and discuss the benefits and other factors. By understanding the different options available, you can make an informed decision about which technology is best suited for your needs. Keep reading to discover more!

What Is Medical Mold Injection Customization (MMIC)?

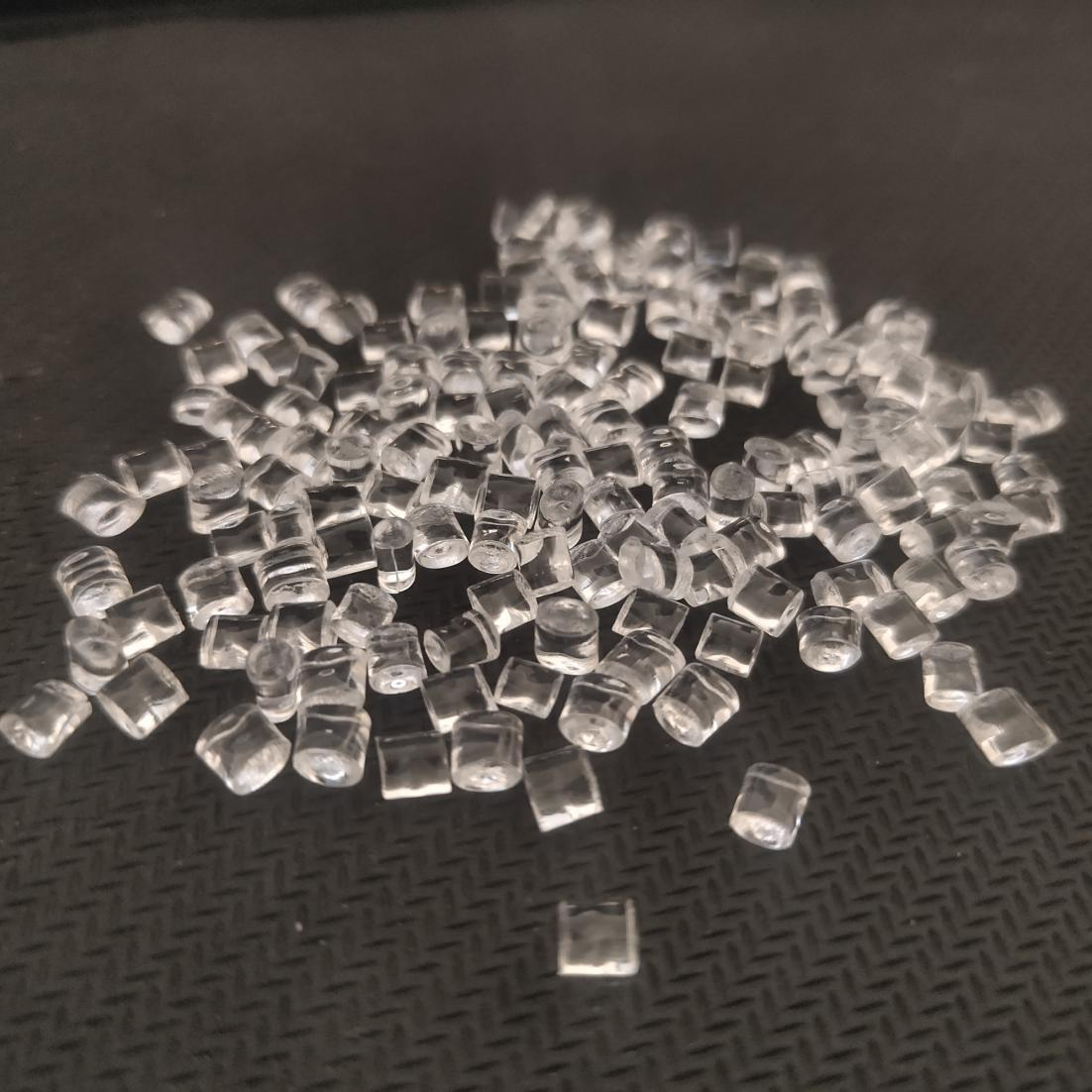

Medical mold injection customization, or MMIC, is a cutting-edge manufacturing technique that is being used to create customized medical devices. This process involves rapidly prototyping prototypes and then using those prototypes to create custom molds for the final products.

Using modern 3D modeling software and advanced polymer materials, MMIC manufacturers can quickly design and build complex parts that perfectly suit the needs of individual patients.

Thanks to its ability to deliver personalized solutions with speed and precision, MMIC is revolutionizing the medical field and helping to improve health outcomes for millions of people around the world.

Whether you need a specific type of stent or an artificial knee joint, with MMIC you can be sure you are getting the best possible treatment option tailored exactly to your needs.

The Importance Of MMIC!

There has been a lot of debate in the industry about the importance of medical mold injection customization.

Some people say that plastic parts don’t need to be customized when producing standard parts, but if you look at the cases where plastic parts need to be customized, you will realize that the importance of MMIC can never be emphasized enough!

Customization is a powerful tool when producing parts that are not standard, and it allows you to overcome existing problems in the market.

For example, if there is a demand for plastic parts that need to have certain aesthetic or functional characteristics, then customization can help you achieve this.

Moreover, having custom-made plastic parts helps ensure competitiveness and improve production efficiency. This is because customized plastic parts can eliminate the need to produce large batches, which in turn reduces costs and increases profitability.

The need to customize plastic parts is increasing as the overall trend of the market emphasizes customer-centric design and exquisite aesthetics. With this shift in focus, medical device companies that want to stay on top of their game need to recognize the importance of MMIC and make it a part of their production process!

That said, although customization is very important in medical mold injection, you also need to be cautious when using it. The entire plastic manufacturing process needs to be very well planned out, so if you do not have enough experience with this process, it is best to consult a professional who can help you with your needs.

Only by working with the right people can you reap the benefits of medical mold injection customization! So start looking for experts today and see how MMIC will change your production process for the better!

How To Choose A Medical Mold Injection Customization Manufacturer?

Choosing a good medical mold injection customization manufacturer can be a very daunting task. It is important to choose one that not only provides you with quality products but also is affordable, reliable, and exceptionally skilled in their field of work.

While choosing a manufacturer for custom made molds, here are some things that you should keep in mind:

1. Molds Have To Be Designed And Manufactured With Care:

The molds need to be designed in a way that can produce parts that satisfy the requirements of their respective industry. You will also want your mold manufacturer to use industry-standard materials in the making of your custom-made molds for medical products, such as polymers, metal alloys, and various other materials.

2. Safety Is Important:

Your manufacturer should provide you with medical-grade products that are safe for use in hospitals and healthcare facilities. This will ensure that your medical devices can safely operate, without the risk of any accidents or injuries occurring due to faulty equipment or molds.

3. Reliability And Affordability:

While it is important to choose a manufacturer that provides you with high-quality medical molds, it is also important to make sure they are affordable and reliable. After all, you will want your medical devices to deliver the best results without breaking the bank or posing any risks!

4. Quality Control:

When looking for a medical mold injection customization manufacturer, it is also important to choose one that has strong quality control measures in place. This will ensure that your medical molds are made with the utmost precision and accuracy, so you can rest assured knowing that you have chosen the best possible manufacturer for your needs.

5. Experienced Staff:

Another important factor to consider when choosing a medical mold injection customization manufacturer is whether or not they have experienced staff on board. This will ensure that your molds are designed and created by professionals who know exactly what they are doing, ensuring a high level of quality control throughout the process.

Overall, choosing the right medical mold injection customization manufacturer is essential to ensuring the success of your medical device. By keeping the above factors in mind, you can be sure to find a manufacturer that will provide you with high-quality, affordable, and reliable molds for your devices!

5 Questions To Ask Potential Medical Mold Injection Customization Manufacturers!

Before you choose a medical mold injection customization manufacturer, it’s important to ask the right questions. This will help ensure that you partner with a company that can best meet your needs and exceeds your expectations. Here are 5 questions to ask potential medical mold injection customization manufacturers:

1. What experience do you have in this field?

2. What is your process for assessing and improving the quality of your services?

3. How do you ensure that your team has the necessary competencies to work on medical mold injection customization projects?

4. Tell me about a time when you helped improve a customer’s product performance or reduce costs through custom medical molding services?

5. What are your company’s core values? How do they guide the way you do business?

Asking these questions will help you get a better understanding of a potential manufacturer’s capabilities, experience, and commitment to quality. Choose a partner that you can trust to deliver high-quality medical mold injection customization services that meet or exceed your expectations.

Top 10 Benefits Of Working With A Reputable And Experienced MMIC Manufacturer!

Finding a reputable and experienced MMIC manufacturer is important for several reasons. They can provide you with high-quality products, support your designs, and help you save time and money.

1. Reputable manufacturers have a good track record of producing quality products.

2. Experienced manufacturers know how to design MMICs that meet your specific requirements.

3. They can provide you with custom designs to get exactly what you need, without any unnecessary features or add-ons.

4. They offer support throughout the design process so that your products are fully optimized for performance and reliability.

5. Reputable manufacturers have a wide range of capabilities and experience working in different markets, so they can help you expand into new industries and markets more easily.

6. Because they work with many different customers, they also have access to a large variety of components and materials, which helps keep costs down while still maintaining quality standards.

7. Their expertise means they can often save you time by recommending efficient processes and methods that will speed up the design process while still producing excellent results.

8. They can also offer valuable insights during the development process so that potential issues are identified and addressed before they become expensive problems.

9. Working with an experienced MMIC manufacturer gives you peace of mind knowing that your products will be backed by a team of experts who are committed to your success.

10. When you work with a reputable and experienced manufacturer, you can be confident that you’re getting the best possible products and services available. This allows you to focus on other aspects of your business, safe in the knowledge that your MMIC needs are being handled by professionals.

Choosing to work with a reputable and experienced MMIC manufacturer is an important decision that can have a major impact on the success of your products.

By taking advantage of their knowledge and expertise, you can be sure that you’re getting the best possible products and services available. This will save you time, money, and stress in the long run, and help you bring your products to market faster and with greater success.

5 Tips For Working With A Supplier To Ensure That Your Needs Are Met!

To meet the needs of medical device manufacturers and ensure that the highest standards for quality are met, it is important to work with a skilled and qualified customization supplier.

To achieve this level of excellence, suppliers must understand the specific requirements associated with producing high-grade medical devices as well as possess the skills necessary to deliver products on time and within budget.

Here are five tips for working with a medical injection molding customization supplier:

- Open communication is key– To ensure that your needs are being met, it is important to keep the lines of communication open with your supplier. This way, you can ask questions and voice any concerns you may have on time.

- Make sure that your supplier has experience in medical injection molding– It is important to work with a supplier who has extensive experience in medical injection molding. This way, you can be confident that they will be able to meet your specific requirements and deliver high-quality products.

- Get quotes from multiple suppliers– Rather than working with the first supplier you come across, it is a good idea to get quotes from multiple suppliers. This will allow you to compare prices and choose the supplier that best meets your needs and budget.

- Make sure that your supplier has high-quality standards– You want to work with a supplier who takes pride in producing high-quality products, as this will ensure that you are receiving the best possible medical devices.

- Consider using an experienced injection molding customization broker– If you need help finding a skilled and reliable medical injection molding customization supplier, it may be helpful to work with an experienced injection molding broker. These professionals can identify reputable suppliers and streamline the process of working with them, making it easier for you to find the right provider for your needs.

Conclusion

When it comes to choosing a medical mold injection customization manufacturer, there are many factors to consider. By keeping the following tips in mind, you can be sure that you are making the best decision for your needs.

RJCmold meets all of these criteria and more, making them the perfect choice for your next medical mold injection customization project. Contact us today to learn more about our products and services or to get started on your project!