Peek is globally recognized as one of the best performing thermoplastics. It is widely used in fields that require extremely high performance, such as medical devices, aerospace, automotive manufacturing, and electronic and electrical industries.

In these fields, there are a large number of PEEK parts that need to be mass-produced, such as sensor housings around automotive engines, precision connectors in electronic appliances, small structural components in medical equipment, etc. These parts can be efficiently produced through PEEK injection molding.

However, PEEK injection molding not only has higher requirements for equipment and mold materials, but also has stricter process control. If Peek is processed using the same process as regular plastic, it can easily lead to the decline in quality, and affect the final performance of the product.

Therefore, in this article, we will share the experience of PEEK injection molding from the following 8 aspects, and its differences from ordinary plastic injection molding. Considering rigorousness, please consult an expert before start your project.

1. PEEK Injection Molding Machine

Because PEEK has characteristics such as high temperature resistance and wear resistance, its melting point reaches as high as 343℃, and the actual processing temperature needs to reach 340 – 400℃. Such a high processing temperature far exceeds ordinary plastics, and ordinary injection molding machines can hardly withstand such high-temperature environments, so a special high-temperature injection molding machine is needed.

In addition, it is best to use a twin-screw design, which can stir and mix the plastic more fully, making PEEK melt more evenly at high temperatures.

The twin-screw design also helps to remove moisture and volatile substances in the plastic, and has strong conveying capacity, which can inject the plastic melt into the mold at a higher speed to improve production efficiency. It should be noted here that in order to extend service life, it is recommended that the screw use wear-resistant alloy material.

Then, usually the L/D ratio is between 18:1 and 24:1, so that the plastic has a sufficiently long residence time and mixing distance in the screw, ensuring full plasticization and uniform mixing.

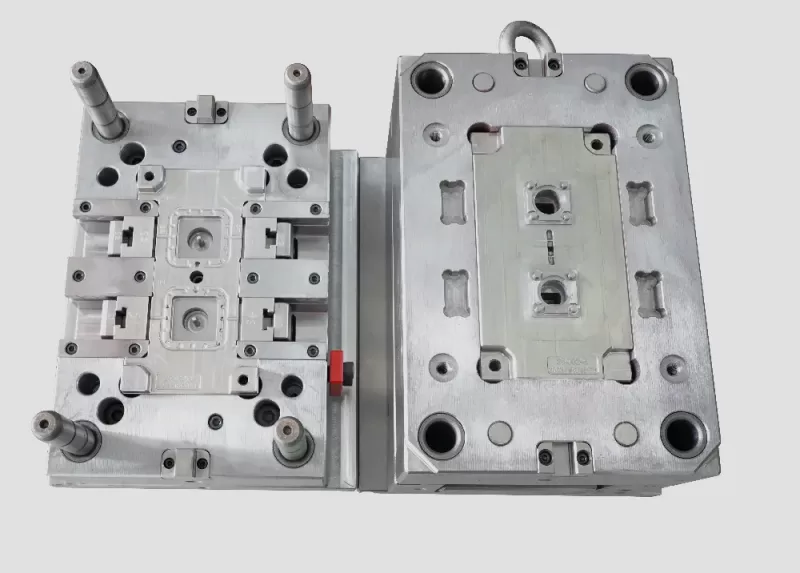

2. PEEK Mold Design

There are also differences between PEEK molds and regular molds. The gate for PEEK needs to be larger, usually designed to be 2/3 of the maximum wall thickness of the product, with a diameter of at least 6mm, in order to ensure good mold filling capability.

As for the cooling system, PEEK molds require spiral waterway cooling, with mold temperature controlled at 40-60℃, and the temperature difference must not exceed 3℃, otherwise warping and deformation are likely to occur. Ordinary plastics are not so strict.

3. PEEK Material Pre-treatment

Because PEEK has relatively strong moisture absorption, it must be dried using drying equipment at 150-180℃ for 3-4 hours before processing to ensure the moisture content is ≤0.02% (ASTM D6287 standard). If not sufficiently dried, the final molded parts may have obvious defects such as silver streaks and bubbles.

In comparison, ordinary plastics like ABS generally only need to be dried at 80-100℃ for two hours.

4. Injection Speed and Holding Pressure

Because PEEK is extremely sensitive to fluctuations in process parameters, injection speed and holding pressure must be precisely controlled. For example, the injection speed is recommended to be maintained between 30-80mm/s, and the holding pressure should be set at 60%-80% of the injection pressure. Ordinary plastics have a higher tolerance; injection speeds can even exceed 100mm/s.

5. PEEK Injection Molding Temperature Requirements

First, the melting point of PEEK is about 343℃, and the barrel temperature needs to reach between 340℃ and 400℃. Only within this temperature range can PEEK fully melt, form a uniform melt, and more easily fill the entire mold, thereby ensuring the integrity and dimensional accuracy of the product. In comparison, ordinary plastics such as PP or PE typically require a barrel temperature of only 160-280℃.

Secondly, in the nozzle part, PEEK requires a fully enclosed heating ring, independently temperature-controlled, and the temperature needs to be controlled at around 380-400℃, to prevent the melt from solidifying in the nozzle. Ordinary plastics are not so particular; the nozzle temperature can even be slightly lower than the barrel, and no extra insulation is needed.

The last temperature requirement is mold temperature. PEEK molds need to be heated to 150-200℃ to achieve ideal crystallinity, while ordinary plastic mold temperatures are mostly between 30-80℃. If the mold temperature is insufficient, the molded PEEK part is prone to amorphous structure, which will result in reduced performance.

6. PEEK Molding Defects

During processing, PEEK will present some unique defects. For example, if the nozzle does not have a retraction function, cold slug points will form; If the moisture content is not up to standard, silver streaks will appear; and black spots may occur due to high-temperature residues. These problems are relatively rare in ordinary plastics.

7. PEEK Post-treatment

To eliminate the internal stress of PEEK parts, complex parts generally need annealing treatment at 200-220℃ for 2-4 hours after molding. Ordinary plastics basically do not need annealing; at most, deburring or spray treatment is performed.

Why complex parts? Because complex parts usually have thicker walls, irregular shapes, or multiple connection points, which make them more likely to generate internal stress during injection molding.

Moreover, the dimensional accuracy and mechanical performance requirements of complex parts are usually higher, so it is necessary to eliminate internal stress to ensure the quality of the parts meets the requirements.

8. PEEK Cost and Production Cycle

Finally, let’s talk about cost and production cycle. The raw material price of PEEK is very high, dozens of times that of ordinary plastics. Currently, the market price of PEEK is between 500,000 to 1.2 million RMB per ton. In contrast, ordinary plastic materials such as PP only cost 10,000 to 20,000 RMB per ton.

In addition, high-temperature injection molding equipment is also 2-3 times more expensive than ordinary equipment.

In terms of production cycle, PEEK cools slowly. Each millimeter of wall thickness may require 20-60 seconds of cooling time, while ordinary plastics usually need only 5-15 seconds.

If you are considering developing PEEK parts, or evaluating whether PEEK is suitable for your project, feel free to contact RJCMold, a processing factory with more than 20 years of injection molding experience. We can provide you with free technical support.

Related post: What is PEEK?