CNC machining is a technology that is widely used in the manufacturing of medical instruments. It can be used to create a wide variety of parts and components with precise dimensions and shapes. CNC machining is a fast and efficient way to produce high-quality parts and components.

CNC machining in medical instrument manufacturing typically involves the use of computer numerical control (CNC) machines. CNC machines are computer-controlled tools that can create highly precise parts and components.

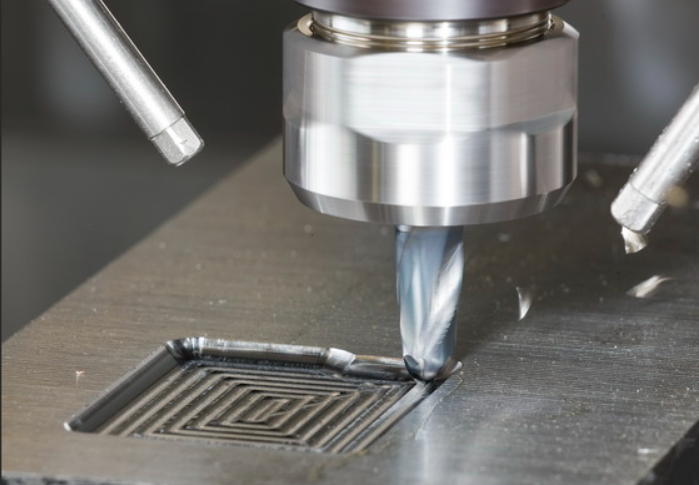

CNC machines are often used to create complex shapes and contours that would be difficult or impossible to create with traditional machining methods. CNC machining can be used to create a variety of different parts and components for medical instruments.

CNC machined parts can be used for everything from medical devices and implants to surgical instruments. CNC machining is an essential part of the manufacturing process for many medical instruments.

Benefits Of Using CNC Machining In Medical Instrument Manufacturing!

There are many benefits to using CNC machining in medical instrument manufacturing. CNC machining can produce parts and components with very tight tolerances.

This means that parts will fit together more precisely, which is essential for medical instruments. CNC machining can also create complex shapes and contours that would be difficult or impossible to create with traditional machining methods.

CNC machining is also very efficient, which can save time and money in the manufacturing process.

CNC machines can operate 24 hours a day, 7 days a week, and can produce large quantities of parts very quickly. CNC machined parts also have a very smooth surface finish, which is important for medical instruments that need to be sterilized.

Overall, CNC machining is an excellent choice for medical instrument manufacturing. It provides many benefits that can save time and money, while still producing high-quality parts.

CNC machining in medical instrument manufacturing can provide many benefits including:

- Tighter tolerances

- More precise fits

- Smooth finishes

- Consistent quality

Each of these benefits can be extremely important in the production of high-quality medical instruments. In many cases, CNC machining is the only way to achieve the level of precision and accuracy required.

- Tighter Tolerances: CNC machining can hold very tight tolerances, which is essential for many medical instruments. In some cases, the tolerance may need to be as low as 0.001” (0.0254 mm). This means that CNC machined parts will fit together perfectly, without any gaps or looseness.

- More Precise Fits: CNC machining can create parts with very precise fits. This is important for medical instruments that need to mate with other parts or components precisely. For example, CNC machined connectors and tubing can be made to fit together perfectly, without any leaks.

- Smooth Finishes: CNC machining can create smooth finishes on parts. This is important for medical instruments that need to have a smooth surface, such as catheters or stents. A smooth finish is also important for parts that will come into contact with human tissue.

- Consistent Quality: CNC machining can produce parts that are identical to each other. This is important for medical instruments that need to be interchangeable, such as implants. It’s also important for instruments that need to be sterilized, as any imperfections could provide a place for bacteria to grow.

How Does CNC Machining Work And What Are The Different Types Of Machines Available On The Market Today?

CNC machining is a process where computer numeric controlled tools are used to create parts from a variety of materials. The first CNC machines were created in the 1940s and were used for industrial applications.

Today, CNC machines are used in a variety of industries, including medical instrument manufacturing. There are three main types of CNC machines available on the market today:

▬ Milling Machines

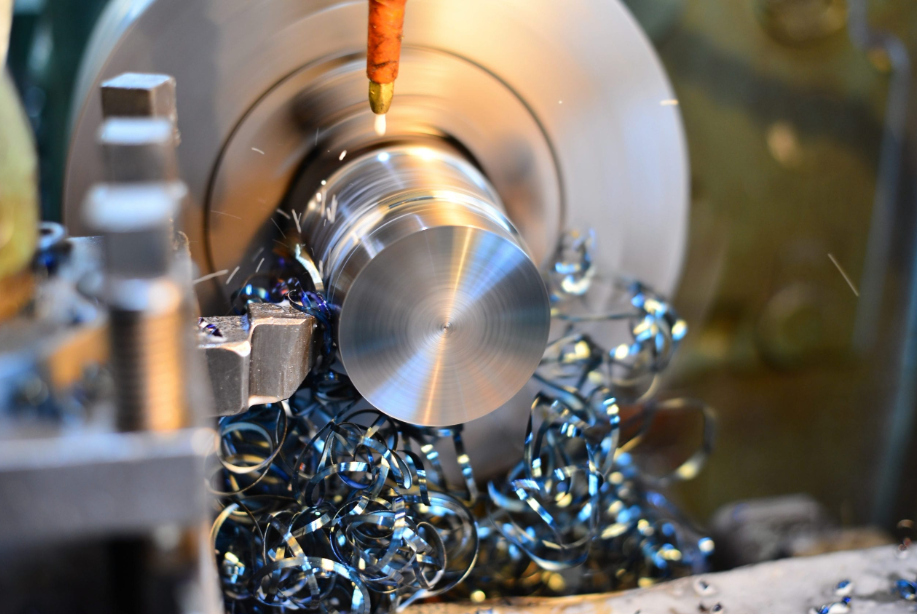

▬ Turning Machines

▬ Machining Centers

Milling machines are the most common type of CNC machine and can be used to create a variety of parts from a variety of materials.

Turning machines are less common, but are used to create parts that require more precise movements, such as screws and other small parts.

Machining centers are the most complex type of CNC machine and can be used to create large, complex parts.

CNC machines are controlled by a computer program that tells the machine what movements to make. The program is written in a CNC programming language, which is a special language that helps the machine understand the instructions.

CNC machines are used in a variety of industries, but they are particularly useful in the medical instrument manufacturing industry. CNC machining allows for the creation of parts with very precise dimensions, which is essential in the medical field.

What Factors Should Be Considered When Choosing A CNC Machine For Medical Instrument Manufacturing?

When choosing a CNC machine for medical instrument manufacturing, several factors should be considered.

- The first factor is the type of medical instruments that will be manufactured. There are different types of medical instruments, and each one requires different machining capabilities. For example, some medical instruments require extremely precise machining, while others may only purpose?

- The second factor to consider is the production volume. How many medical instruments will need to be produced? Once again, this will dictate the type of CNC machine needed.

If only a low volume of medical instruments will be produced, then a lower-end CNC machine may suffice. However, if a high volume of medical instruments will be produced, then a higher-end CNC machine will be necessary.

- The third factor to consider is the budget. What is the budget for the CNC machine? There is a wide range of prices for CNC machines, so it is important to find one that fits within the budget.

- The fourth and final factor to consider is the level of experience with CNC machines. If this is the first time using a CNC machine, then it is important to find one that is user-friendly and comes with good instructions.

Once all of these factors have been considered, it will be easier to choose the right CNC machine for medical instrument manufacturing. With the right machine, medical instrument production can be streamlined and made more efficient.

What Are Some Of The Challenges That Manufacturers Face When Incorporating CNC Machining Into Their Production Processes?

When it comes to medical instrument manufacturing, there are a few key considerations to take into account. First and foremost, CNC machining is a highly precise process that requires tight tolerances to produce accurate results.

This can be challenging for manufacturers who are not accustomed to working with such tight tolerances. In addition, CNC machining often produces large amounts of heat, which can damage sensitive components within medical instruments.

As a result, manufacturers must take care to properly cooled their tools and workpieces during the machining process.

Another challenge that manufacturers face when incorporating CNC machining into their production processes is the high cost of CNC machines. While the initial investment may be higher than traditional machining methods, the long-term costs associated with CNC machining are often lower.

This is because CNC machines can produce parts with greater precision and consistency, which leads to less waste and scrap. In addition, CNC machines typically have a longer lifespan than traditional machining equipment, so manufacturers can enjoy years of production before needing to replace their machinery.

Despite the challenges that manufacturers face when incorporating CNC machining into their medical instrument manufacturing processes, the benefits of this technology often outweigh the drawbacks.

CNC machining provides manufacturers with a versatile and precise way to create complex parts for a variety of medical devices and instruments. When used properly, CNC machining can help manufacturers improve the quality of their products while also reducing costs and lead times.

How Can CNC Machining Improve The Quality And Efficiency Of Medical Instruments Produced By Manufacturers Worldwide?

In the medical field, precision is key. From scalpels to stents, implants to pacemakers, the devices, and instruments used by healthcare professionals must meet stringent standards of quality and accuracy.

Any deviation from these standards can have serious consequences. This is where CNC machining comes in. CNC, or computer numerical control, machining is a manufacturing process that uses specialized software to control machine tools. This allows for the precise fabrication of parts and devices with a high degree of accuracy.

In the medical field, this can be critical for ensuring that instruments function as intended and meet the necessary safety standards. CNC machining can also help to improve the efficiency of production, reducing turnaround times and ultimately benefiting patients.

In addition, CNC machining can be used to create customized instruments that are specifically designed for a particular patient’s needs.

As medical technology advances, the use of CNC machining will become increasingly important in the manufacture of high-quality medical instruments.

For these reasons, CNC machining is playing an increasingly important role in the manufacture of medical instruments worldwide.

What Trends Are Emerging In Medical Instrument Manufacturing, And How Will CNC Machining Help To Meet These Demands?

CNC (computer numerical control) machining is a process that uses computer-controlled tools to create accurate and repeatable parts and components. This technology has a wide range of applications, including the manufacturing of medical instruments.

As the healthcare industry continues to evolve, new trends are emerging in medical instrument manufacturing. These trends include an increased focus on miniaturization, safety, and patient comfort. CNC machining is well-suited to meet these demands, as it offers high levels of accuracy and repeatability.

In addition, CNC machined parts can be produced quickly and efficiently, making this technology an ideal choice for medical instrument manufacturers.

In the future, CNC machining is likely to help meet the demand for ever-more sophisticated medical instruments.

Case Study – How A Leading Medical Instrument Manufacturer Used CNC Machining To Improve Their Production Process!

In one case study, a leading medical instrument manufacturer used CNC machining to improve its production process. The manufacturer had been using traditional machining methods but was struggling with maintaining consistent quality across their products.

They decided to switch to CNC machining to improve the accuracy of their parts. After making the switch, the manufacturer was able to reduce scrap rates by 30% and increase productivity by 20%.

CNC machining allowed them to produce consistently high-quality products, which helped them to improve their reputation in the marketplace.

In another case study, a leading medical instrument manufacturer used CNC machining to improve its production process. By switching to CNC-produced parts, the company was able to reduce production time by 60%.

In addition, CNC machining allowed for greater precision in the manufacturing process, resulting in better-quality products. As this example shows, CNC machining can be an invaluable tool in the medical industry.

How Has The Use Of CNC Machines Changed Over The Years, And Where Is It Headed In The Future?

CNC machines have come a long way since they were first introduced in the 1950s. Initially, CNC machines were used primarily for manufacturing large objects such as aircraft parts and car engines.

However, advances in technology have led to the development of smaller, more precise CNC machines that are capable of creating intricate shapes and patterns. Today, CNC machines are commonly used in the medical field for the manufacture of prosthetics and other medical devices.

In the future, CNC machines will likely continue to become more compact and versatile, making them even more useful for a variety of applications. As CNC technology continues to evolve, the possibilities are endless.

Looking to the future, it is likely that CNC machines will continue to become more widely used as they become more affordable and easy to use.

Additionally, CNC machines are likely to play an increasingly important role in prototyping and small-scale production. As technology continues to evolve, the possibilities for CNC machines are endless.

Conclusion

Thanks to CNC machining, the medical instrument manufacturing industry is constantly evolving and improving, providing patients with safer and more effective treatments.

When it comes to quality and accuracy, CNC machining is often the best option for producing small, complex parts with tight tolerances. If you’re looking for a partner who can help you with

CNC machining or any other aspect of medical instrument manufacturing, contact RJCmold today. We would be happy to discuss your needs and see how we can help you create products that meet the highest standards in the industry.