Insert molding is a precise manufacturing process that involves inserting a pre-made component into a mold cavity, such as metal or plastic components, then injecting plastic material around it to form a finished part by injection machine. To get a final single part that combines the characteristics and functionality of both the insert and the plastic material.

The tips need to consider during the insert molding process

Design considerations: The insert design should be compatible with the mold design and the injection molding process. The insert should have proper draft angles, clearances, and surface finishes to facilitate easy insertion and removal from the mold. The location and orientation of the insert within the mold should also be considered to ensure proper flow of the molten material and minimize the risk of defects. And also need to consider the insert would not scratch or damage the actions in production, put the insert into the mold during the injection, and take it out of the mold. Each action needs to avoid these risks.

Material selection: The material of the insert should be compatible with the plastic material used in the injection molding process. For the plastic insert, the coefficient of thermal expansion and the melting point of both materials should be similar to avoid warping or cracking of the finished part. If the insert is metal, you don’t need to consider this issue. Many products in our daily life have metal with plastic, such as different connectors for cars, computers or medical equipment, etc., and lots of electronic housing with brass nuts or AL nuts to make the products stronger.

Insert preparation: The insert should be cleaned and free from any contaminants or debris affecting the bonding between the insert and the plastic material. Some inserts may require pre-treatment, such as sandblasting or an adhesive layer, to enhance the adhesion properties.RJC made many metal insert products, some of them need plating, Cu+Ni+gold plating, like the car connectors. Some use Cu directly, and some use AL with Cu+Ni+Silver plating for an electric vehicle.

Mold preparation: The mold should be designed and manufactured to accommodate the insert and ensure proper alignment and positioning. The mold should also have a robust clamping mechanism to hold the insert during injection molding. Mostly, many insert molds are needed highly precise manufacturing to reduce the risks in future production, so it needs high lever equipment, a high-speed CNC center, mirror EDM, a slow-feeding wire cut machine, etc., also need CMM measurement machine support to control the quality of the whole machining processes.

Injection molding process: The injection molding process should be optimized to ensure proper flow of the plastic material around the insert and minimize the risk of defects, such as voids, sink marks, flashes, or warping. The process parameters, such as temperature, pressure, and cooling time, should be carefully monitored and adjusted to achieve consistent and high-quality parts.

Shenzhen RJC Industrial CO., LTD (rjcmold.com) dedicating to mold manufacture for many years and has also produced thousands of plastic molds. Among them, more than one thousand insert molds.

Below is a true case study of RJC for insert mold

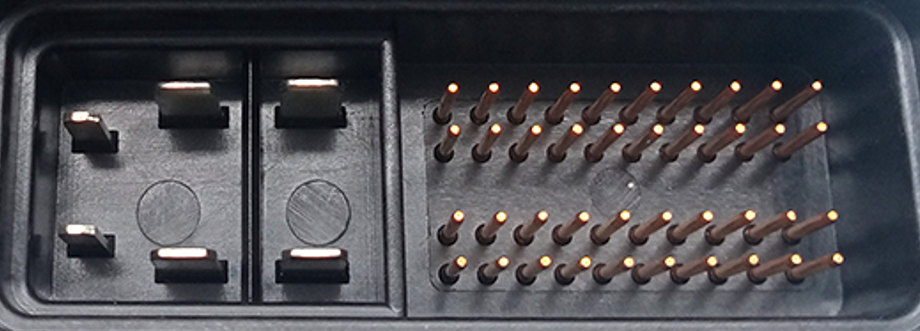

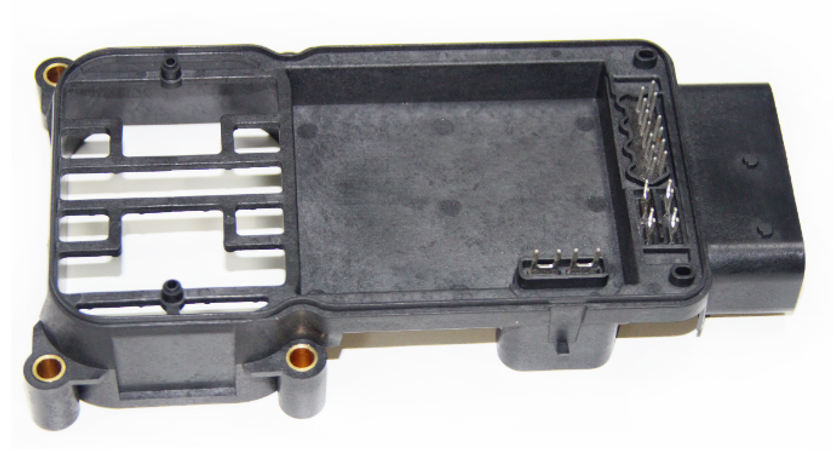

This insert product is a connector for a vehicle; the plastic material uses PPA with glass fiber. It’s a hard material and would not easily have flashes. There’s a big problem with RJC producing this product, except for a few insert issues.

The processes:

Put all the pins into a mold to do an injection to get the block with pins, then put this block into the final mold to get the final products. It can reduce the wide area to avoid sink marks.

During the injection process, what issues that we face? One is the pins scratch and damage the plating surface. Based on the current situation, we design a bakelite block to protect the pins, and put it into the mold through the injection molding process, then take it off after the products come out. Because of the injection pressure, it needs a gap to allow the pin to move a small distance, and it also guarantees it can not flash. Another one is that the pin is easily oxidized, so we changed the plating process and strengthened quality control. This is a technical case with challenges. So, we had several meetings to discuss and analyze the tech, process control, and find solutions. The good thing is these actions are helpful. We finished and reached the clients’ requirements.

RJC is a professional mold maker. Welcome to contact us to start your project.

Always provide the best engineering and manufacturing support to you. Offer the best price and do a design for manufacture report(DFM)to check for any issues and then make an improvement. That’s very helpful on all the molding projects.

Good luck.