Introduction

Manufacturers need CNC prototype machining services because they want their prototypes evaluated and tested.

It is after this that they can start the production of those parts. If the parts are not up to the mark, then they are rejected. It helps in avoiding any accidents that might occur.

These parts are ordered by people who work in the automotive, electrical, defense, or medical industry.

What Is Prototype Machining

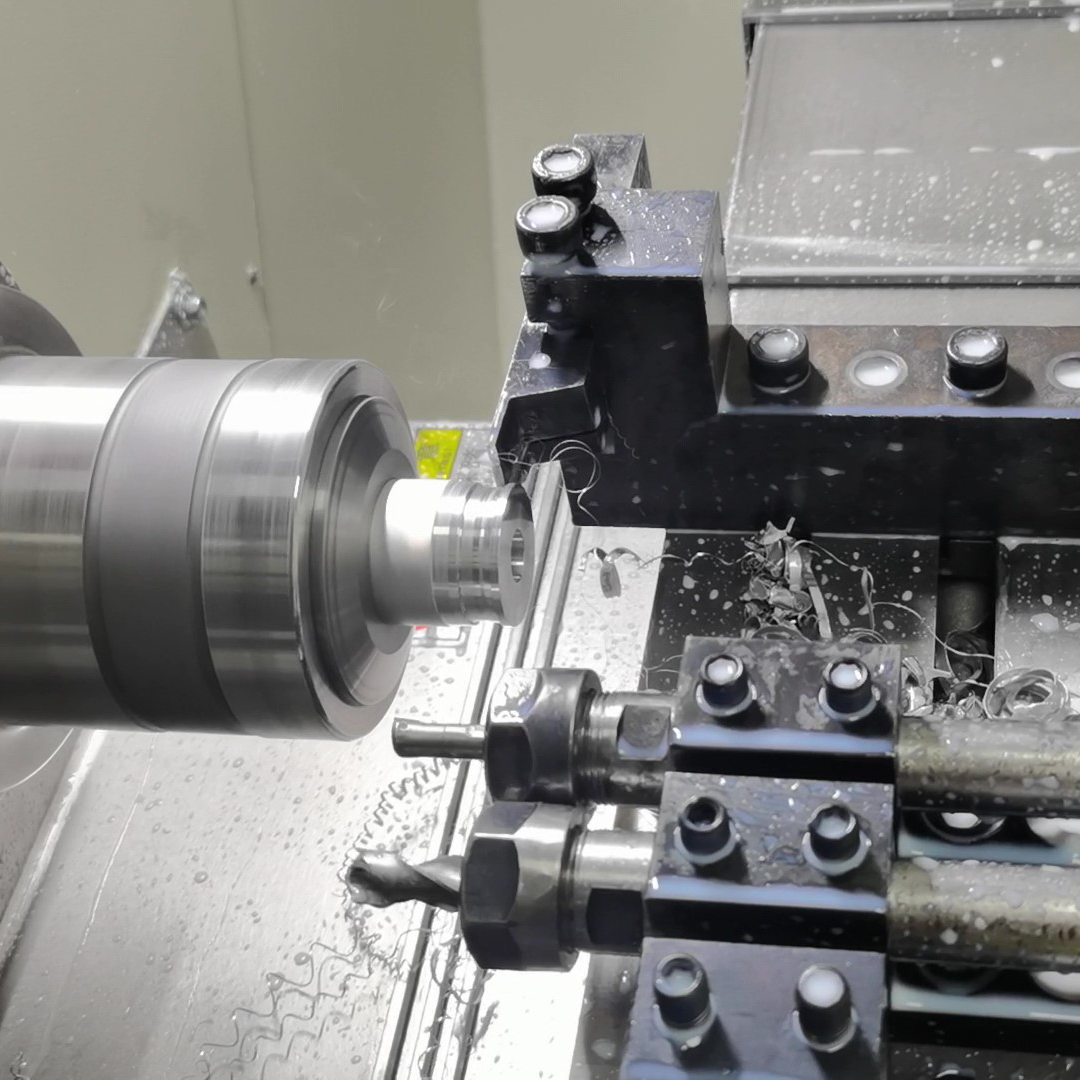

Required parts are made from a block of raw material using computer machines. RJC inputs CAD designs and manufactured parts are made.

It is not similar to 3D printing. In 3D printing, many layers of the material are created for the result, but it is not the same in prototype machining.

In prototype machining, the machine removes the material by cutting it. This process removes unnecessary material and makes the parts according to the CAD design.

We usually use a small batch of prototypes for better results.

Some of the advantages of using our prototype machining for product development are listed below.

- Fast

If you think that your raw material is rigid, you have come to the right place. It is the fastest way for making parts.

New technological developments have made it even easier for companies like ours to make your parts quickly.

Even the setup and processing time are faster than the rest. It is by far a faster process. You will get your semi-finished part or finished part in a short period.

In prototype manufacturing, the 3D parts are added as G-codes. G-codes are used by the machine to make the desired parts. It gets ready in a few minutes only.

The file is created in a few hours whereas the actual cutting process takes just a few minutes. As soon as you think about a specific part, you can get it in a matter of a few hours.

It will then be evaluated by us and the client. This way you can start your production in just a day. Approving the molds is a very long process.

Injection molding is much faster, depending on the parts.

After this, the parts are measured, painted, and go through the second process.

- Accurate

Our prototype machining can create exact 3D models. Once we have entered the instructions into the computer, then the computer will only follow those instructions.

Its movements are controlled and help it to create an accurate model. Since a machinist cannot make the prototype, the accuracy is high. There is no tolerance for any mistake.

We work on many projects at the same time, so this accuracy is repeatable. For a few microns, we dial intolerance.

Everything is just a button away. Just by changing a few things, we can make a unique prototype.

- Fixed Tools Are Not Needed

Required molds made from other types of prototyping techniques need days or even weeks. In this type of prototyping, no tools are needed.

We only attach inserts to the spindle. No problems arise as these inserts can be changed at any time. It only takes a few seconds to change them.

- Flexibility

There is not much difference if you want to get one part of a hundred made. CNC rapid prototyping can produce as many as a few hundred parts in a matter of some hours.

New developers are not sure as to how will their customers react once they launch their product. To save the production cost, they can get a few of their products made in a short period.

Once they need more products, they can order as many as a few hundred, and it will be on their doorsteps by the end of the day.

This type is for you if you do not have an inventory or you think you will never need one. It is unnecessary to carry many products when you can get them made on-demand.

- Modification

You do not have to worry about changing anything in your design at any time. If your design is halfway through and you feel like you need a few changes, you can always reach out to us.

By changing a few lines in the codes, we can change your prototype at any point in time. Once the end product is in our hands, we test them out.

We evaluate the results and change the design if you’re not satisfied with the results. It gives you the chance to change the design as many times as you want.

This technique saves your time and money. We will never let you go into full production, only to see that the parts do not work. You can now test these parts before starting your production process.

- Variety Of Materials

We do not tell you to go for the material that you do not desire. It will always be your choice when making a decision.

With this type of technique, you can choose from many materials which are at your disposal. You must note that these materials should be hard enough for the process to take place without any problem.

As manufacturers, we must use the same material that you require in their final product. We believe that product designers must use this method to make prototypes.

It makes it possible for CAD to not lose anything from its code.

Your choice comes first! We help you get the best raw material and process. CNC milling and turning work on almost every material.

Some examples are plastics, nickel, aluminum, stainless steel, and many more. We would advise you to not worry about choosing the correct material.

We’re always here for you. We will help you find the best raw material for your end product to stand out.

We believe that you should first select a less expensive material. It will help you reduce the cost if you’re not satisfied with your end product.

Once the design is finalized then you can go for the perfect material. Aluminum is less expensive than other raw materials, and once the design is perfect, you can get it made in steel. This way you will save your development cost.

- Quality

Quality is a benefit that you can get when you use prototype machining. For more strict requirements, you must go for it.

Quality is not just limited to the raw material and the shape of the design. It shows in the appearance and the surface of the product.

We believe that your end product should not go through any more processes once it is made. This technique uses the correct tools and speed for your design.

This saves your time and money. You can use this money for other needs.