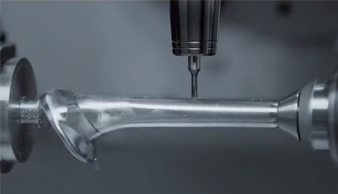

CNC Machining In Medical Instrument Manufacturing!

CNC machining is a technology that is widely used in the manufacturing of medical instruments. It can be used to create a wide variety of parts and components with precise dimensions and shapes. CNC machining is a fast and efficient way to produce high-quality parts and components. CNC machining in medical instrument manufacturing typically involves the use of computer numerical control (CNC) machines. CNC machines are computer-controlled tools that can create highly precise [...]